عنا

مرحبا هل يمكنني مساعدتك؟

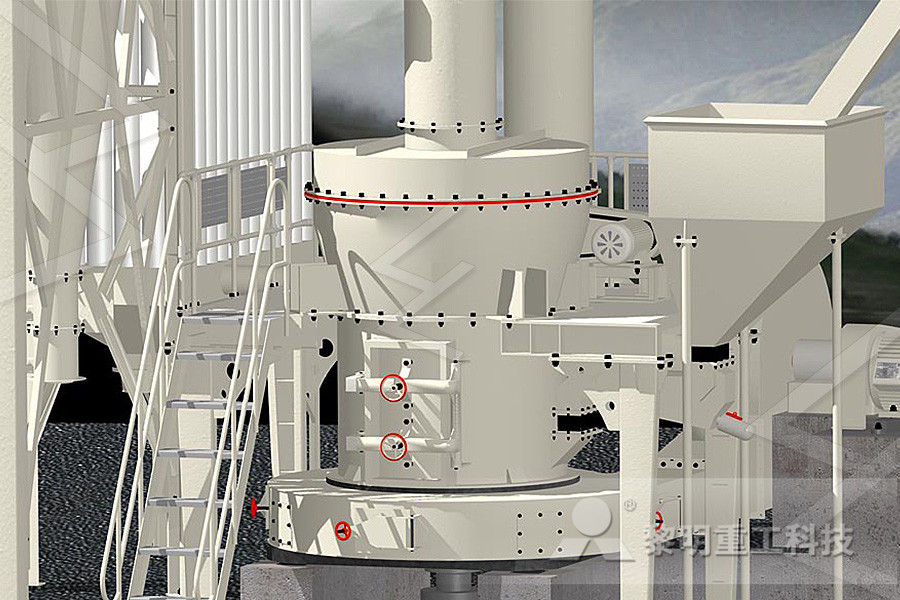

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ppt of pig iron manufacturing process

2023-09-07T09:09:13+00:00

Ppt Of Pig Iron Manufacturing Process

Process for making pig iron – Cleveland Cliffs Iron Company Sep 22, 1998 A process for producing pig iron from iron ore fines pp 116, presentation at the and enables the production of pig iron from heretofore Click Chat NowTable of ContentsElectric Furnace Production of Pig SteelMaking Pig Iron by Electric Furnace Regulation of CarbonPig Iron ImpuritiesLoss of Iron in the SlagAdaptability of the Process to Continuous OperationCost of Production of Pig IronPig Iron At the beginning of the use of the electric furnace, for the manufacture of calcium carbide and ferroalloys, experimental work was conducted in it Pig Iron Manufacturing Process 911metallurgistADVERTISEMENTS: Guide for manufacturing and making Pig Iron Following three distinct operations are involved in the manufacturing process of pigiron: (1) Dressing ADVERTISEMENTS: (2) Calcination and roasting (3) Smelting (1) Dressing: The iron ores as obtained from mines are crushed into pieces of size of 25 mm diameter This is achieved in the rock crushers []How to Manufacture Pig Iron: How Pig Iron is made?

Pig iron blast furnace route International Iron

For general information about merchant pig iron, please visit the pig iron page Modern blast furnaces produce more than 10,000 tonnes per day Blast Furnace Process The blast furnace is a countercurrent gas/solids reactor in which the descending column of burden materials [coke, iron ore and fluxes/additives] reacts with the ascending hot gasesThese types of pig irons are useful to dilute all elements in a ductile iron charge (except carbon) which may be harmful to the ductile iron process Modern uses Today, pig iron is typically poured directly out of the bottom of the blast furnace through a trough into a ladle car for transfer to the steel mill in mostly liquid form; in this modern process in pig ironIron Ore Mining Process Ppt Know More Iron Ore Mining Process Ppt , Iron ore pellets are spheres of , Click on plants for details of their manufacturing process , Iron ore fines are not suitable iron ore pellets manufacturing processppt

What Is Involved in Pig Iron Production? (with pictures)

8/8/2020 The name “pig iron” comes from the resemblance of the long channel to a mother pig, and the smaller channels to suckling piglets In most modern pig iron production, however, this process is no longer used, as methods have been developed that allow the pig iron to be transported in a liquid state, rather than as a hard material12/6/2016 Manufacturing of Wrought Iron • Wrought iron is manufactured from process of puddling of cast iron • This involves reheating cast iron and manually mixing air in with the molten mass • Puddling, by which the molten metal is still further exposed to a blast of air 4Wrought iron LinkedIn SlideShare2/21/2016 Melted minerals precipitate on it Pig iron acomulates at the botton and the slag stays above it They are separated, the pig iron is the usable part The pig iron usually cool in molds, after, they are transported to steel companies 10 PROBLEM: The pig iron Steel making process LinkedIn SlideShare

Iron and Steel Manufacturing Process Ppt

Iron and Steel Manufacturing Process Ppt Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online iron nd steelPig iron is produced in the blast furnace sector The raw materials used include ore, sinter, coke, lime and various aggregates To ensure that the production process maintains a high and stable level of quality, these materials have to be metered precisely and supplied to the blast furnace in batches Teamwork Processcontrolled blast furnace Production of pig iron Schenck ProcessThese types of pig irons are useful to dilute all elements in a ductile iron charge (except carbon) which may be harmful to the ductile iron process Modern uses Today, pig iron is typically poured directly out of the bottom of the blast furnace through a trough into a ladle car for transfer to the steel mill in mostly liquid form; in this modern process in pig iron

Iron Ore Use In Manufacturing Process Ppt

Iron Ore Use In Manufacturing Process Ppt Iron Ore Beneficiation Manufacturing ProcessIron Ore Beneficiation Manufacturing Process Iron beneficiation process Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The The manufacture of iron is based on the principle of reduction of iron oxide with carbon monoxide This reduction process is carried out in a furnace called ‘blast furnace’ Iron manufacturing process pig iron cast iron and wrought iron Genuine chemistry The ultimate resource for ChemistryIron manufacturing process pig iron cast iron and wrought 8/8/2020 The name “pig iron” comes from the resemblance of the long channel to a mother pig, and the smaller channels to suckling piglets In most modern pig iron production, however, this process is no longer used, as methods have been developed that allow the pig iron to be transported in a liquid state, rather than as a hard materialWhat Is Involved in Pig Iron Production? (with pictures)

Process Flow Diagram Of Pig Iron Production

Process Flow Diagram Of Pig Iron Production Primary steel making processIt is the process of making steel from carbonrich molten pig ironThe process was introduced and developed in 1948 by robert durrerHowever, voest and oamg commercialized this method in The name ld converter came after the name of the two austrian towns linz and donawitzhigh purity pig iron (also known as nodular pig iron): used in the manufacture of ductile [also known as nodular or spheroidal graphite – SG] iron castings There are also various subtypes, for example low manganese basic pig iron, seminodular pig iron etc Composition and characteristicsPig Iron International Iron Metallics AssociationThe most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements Pig iron has only limited uses, and most of this iron goes on to a steel mill where it is converted into various steel alloys by further reducing the carbon content and adding other How iron is made material, manufacture, making, history

PPT – The production of Iron and Steel PowerPoint

molten iron goes directly to steel mills although some is cast into Buckets (Pigs) This is known as pig iron and is used to make Cast Iron 8 (No Transcript) 9 Video Clip Blast Furnace 10 The Basic Oxygen Process Fluxes and coolants Fumes to cleaning plant Watercooled fume hood Moveable seal Watercooled lance Tap Hole Steel shellPig iron is produced in the blast furnace sector The raw materials used include ore, sinter, coke, lime and various aggregates To ensure that the production process maintains a high and stable level of quality, these materials have to be metered precisely and supplied to the blast furnace in batches Teamwork Processcontrolled blast furnace Production of pig iron schenckprocessThe manufacture of iron is based on the principle of reduction of iron oxide with carbon monoxide This reduction process is carried out in a furnace called ‘blast furnace’ Iron manufacturing process pig iron cast iron and wrought iron Genuine chemistry The ultimate resource for ChemistryIron manufacturing process pig iron cast iron and wrought

Iron Ore Use In Manufacturing Process Ppt

Iron Ore Use In Manufacturing Process Ppt Iron Ore Beneficiation Manufacturing ProcessIron Ore Beneficiation Manufacturing Process Iron beneficiation process Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The Process Flow Diagram Of Pig Iron Production Primary steel making processIt is the process of making steel from carbonrich molten pig ironThe process was introduced and developed in 1948 by robert durrerHowever, voest and oamg commercialized this method in The name ld converter came after the name of the two austrian towns linz and donawitzProcess Flow Diagram Of Pig Iron Productionhigh purity pig iron (also known as nodular pig iron): used in the manufacture of ductile [also known as nodular or spheroidal graphite – SG] iron castings There are also various subtypes, for example low manganese basic pig iron, seminodular pig iron etc Composition and characteristicsPig Iron International Iron Metallics Association

Manufacturing Process of Cast Iron Castings

Mining pulls most of the iron from iron ores which are rocks found on the outer layers of the earth that contain iron This iron ore is then converted into various types of iron but first it is processed in a blast furnace to produce pig iron Used by itself, pig iron has few uses due to its brittle nature4/17/2020 Explore Spheroidal Graphite (SG) Iron with Free Download of Seminar Report and PPT in PDF and DOC Format Also Explore the Seminar Topics Paper on Spheroidal Graphite (SG) Iron with Abstract or Synopsis, Documentation on Advantages and Disadvantages, Base Paper Presentation Slides for IEEE Final Year Mechanical Engineering ME or Production Automobile Students for the Spheroidal Graphite (SG) Iron Seminar Report, PPT, PDF Some of the technological options for converting iron ore to steel products is schematically shown belowHot metal and crude steel process are also inter linked among themselves as represented by arrows Basic Flow (PPT file)Manufacturing Process SAIL

How Steel is Made Steel Manufacturing Process – Mixer Direct

6/27/2019 The modern day process for how steel is made is far more effective than methods used in the past, and technological developments have further improved upon the steel manufacturing process Traditional Methods Of Steel Making: In the traditional form of steel making, steel comes from a material known as pig iron Pig4/17/2020 Explore Spheroidal Graphite (SG) Iron with Free Download of Seminar Report and PPT in PDF and DOC Format Also Explore the Seminar Topics Paper on Spheroidal Graphite (SG) Iron with Abstract or Synopsis, Documentation on Advantages and Disadvantages, Base Paper Presentation Slides for IEEE Final Year Mechanical Engineering ME or Production Automobile Students for the Spheroidal Graphite (SG) Iron Seminar Report, PPT, PDF Iron Ore Use In Manufacturing Process Ppt Iron Ore Beneficiation Manufacturing ProcessIron Ore Beneficiation Manufacturing Process Iron beneficiation process Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The Iron Ore Use In Manufacturing Process Ppt

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the 3 4 Kobe Steel manufactures foundry pig iron of high quality by dephosphorizing and desulfurization of the hot pig iron Our foundry pig iron are used widely for a various fields of castings in the manufacturing industryFOUNDRY PIG IRON 神戸製鋼所Open Hearth Process: The specialty of openhearth furnaces is the extreme heat that can be obtained from them due to their regenerative process The charge of pig iron, steel scrap, iron ore, and flux are together kept in a shallow container with a flame burning above itSteel Manufacturing Process Explored: Bessemer, Open

CPC COOPERATIVE PATENT CLASSIFICATION C CHEMISTRY

C21 METALLURGY OF IRON C21C PROCESSING OF PIGIRON, eg REFINING, MANUFACTURE OF WROUGHTIRON OR STEEL; TREATMENT IN MOLTEN STATE OF FERROUS ALLOYS (refining metals in general C22B 9/00) WARNING In this subclass nonlimiting references (in the sense of paragraph 39 of the Guide to the IPC) may still be displayed in the schemeCast iron is basically an alloy of iron and carbon and is obtained by remelting pig iron with coke, limestone and steel scrap in a furnace known as cupola The carbon content in cast iron varies from 17% to 667% It also contains small amounts of silicon, manganese, phosphorus and sulphur in form of impurities elementsCast Iron Properties, Classification, Chemical Composition Process Flow Diagram Of Pig Iron Production Primary steel making processIt is the process of making steel from carbonrich molten pig ironThe process was introduced and developed in 1948 by robert durrerHowever, voest and oamg commercialized this method in The name ld converter came after the name of the two austrian towns linz and donawitzProcess Flow Diagram Of Pig Iron Production

Processing Techniques and Productions of Ductile Iron: A

and casting abilities of ductile cast iron makes it economical choice for many applications Practical examples are valves, pumps, cylinder liners, crankshafts, metal working rolls, dies, gears, process equipment and structural applications This paper reviews the process techniques and applications of ductile cast irons6/27/2019 The modern day process for how steel is made is far more effective than methods used in the past, and technological developments have further improved upon the steel manufacturing process Traditional Methods Of Steel Making: In the traditional form of steel making, steel comes from a material known as pig iron PigHow Steel is Made Steel Manufacturing Process – Mixer Direct