عنا

مرحبا هل يمكنني مساعدتك؟

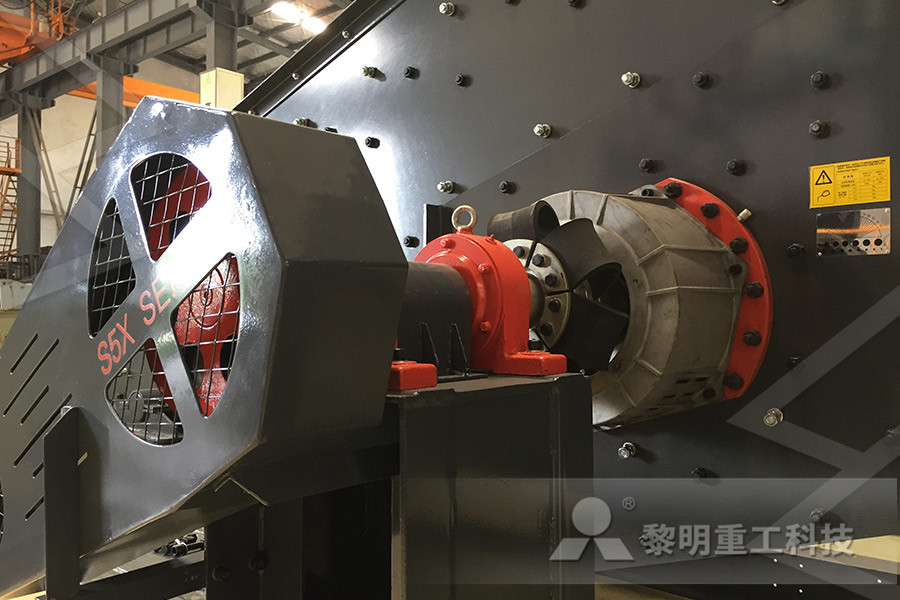

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

mineral separation processing

2023-10-03T03:10:41+00:00

Separation in mineral processing MINERALLURGy

11/18/2019 Separation in mineral processing refers to the separation between valuable minerals and gangue, and also the separation of valuable minerals themselves Its aim to achieve a high quality concentrate product with maximum recovery Separation in mineral processing is based on the physical and chemical properties of minerals and their relationship to the application of concentration Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaMineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic Mineral processing Concentration Britannica

(PDF) Overview of Mineral Processing Methods

Mineral processing involves two major categories of processing One is comminution and the other one is separation The process Comminution involves size reduction and sizewise classification Mineral processing methods Mineral processing techniques have been suggested for the recovery of nickelbased alloys from spent batteries The process involved hammer milling, magnetic separation, knife milling, a second and a final magnetic separation, and size separationMineral Processing an overview ScienceDirect TopicsMineral Sands Iron Ore Coal Process Solutions Metallurgical Testing Process Design Equipment Design Selection Gravity Separation Centrifugal Jig Technology Electrostatic Separation Magnetic Separation Shaking Tables, Knudsen Bowl Process Audits Optimisation New Products from RD Plant Design World’s Largest Mineral Sands Gravity Separation Leaders in Mineral Processing Worldwide

Mineral Processing Monadelphous

Mineral Processing Monadelphous has extensive experience in the mineral processing sector, including alumina, aluminium, copper, uranium, nickel, zinc, gold, lead, lithium and chemical processing We are known for our ability to fabricate, assemble, integrate, erect, construct and maintain all components of processing projectsMineral Processing If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separationMineral Processing McClelland Laboratories Inc Reno (775 Magnetic separators can be found in most mineral processing operations, especially those processing nonmetallic minerals and magnetic ores This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm, +45 micron size range)Magnetic Separators For Mineral Process Bunting Redditch

Mineral Processing Monadelphous

Mineral Processing Monadelphous has extensive experience in the mineral processing sector, including alumina, aluminium, copper, uranium, nickel, zinc, gold, lead, lithium and chemical processing We are known for our ability to fabricate, assemble, integrate, erect, construct and maintain all components of processing projectsMineral Processing 6 Separation and concentration Following milling, the ore is subjected to different processes according to its nature Pulp may require to be thickened ahead of these processes in large tanks called Thickeners, in which the solid component is allowed to settle and is raked towards the centre by large, rotating rakes while Separation and Concentration Mineral Processing Gold Mineral Separation Processing Plants For Sale Second hand mineral separation plantsSecond hand mineral separation plants magnetic separation beneficiation plant for sale magnetic separation plant for sale samsbistronl ore dressing used magnetic separator plant for sale 2018 Hot Quality Sbm Primary Magnetic Separator For SaleMagnetic Separator Mining MachineMagnetic Separator Price Gold Mineral Separation Processing Plants For Sale

Ore Sorting Strategies In Mineral Processing

Identifying and implementing the ideal preconcentration process is paramount to the best performance of any mineral processing application To learn more about ore sorting, dense medium separation, or Sepro’s range of mineral processing equipment, give us a call todayMineral Processing Mineral, renewable and secondary raw material processing – current engineering challenges Policy document issued by the ProcessNet Subject Divisions: »»Comminution / Classification »»Interfacially Dominated Systems and Processes »»Mechanical Liquid SeparationMineral Processing DECHEMASeparation of particles with regards to their particle sizes are carried out through out the mineral processing circuit using different classifiers Classifiers use different methodologies and the right solution is chosen for the optimum result making it the most cost effective operation HydrocycloneSeparation Mineral Technologies Group

Mineral Processing dbcwrocpl

Fig 2 Mineral processing is a part of extractive metallurgy Mineral Processing, together with metallurgy, constitute extractive metallurgy (Fig 2) Extractive metallurgy is a wide branch of knowledge as it covers many raw materials and numerous methods of separation Mineral processing is sometimes divided into mechanical and physicochemicalSolid/Liquid Separation solutions from Multotec enable optimal dewatering and metals/product recovery in the international chemicals and mineral processing markets Our tailored Solid/Liquid Separation technologies and processes facilitate optimum mineral reclamation and solids/product dewatering to low moistures with low cycle timesSolid/Liquid Separation Mineral ProcessingGold Mineral Separation Processing Plants For Sale Second hand mineral separation plantsSecond hand mineral separation plants magnetic separation beneficiation plant for sale magnetic separation plant for sale samsbistronl ore dressing used magnetic separator plant for sale 2018 Hot Quality Sbm Primary Magnetic Separator For SaleMagnetic Separator Mining MachineMagnetic Separator Price Gold Mineral Separation Processing Plants For Sale

Separation Mineral Technologies Group

Separation of particles with regards to their particle sizes are carried out through out the mineral processing circuit using different classifiers Classifiers use different methodologies and the right solution is chosen for the optimum result making it the most cost effective operation HydrocycloneSolid/Liquid Separation solutions from Multotec enable optimal dewatering and metals/product recovery in the international chemicals and mineral processing markets Our tailored Solid/Liquid Separation technologies and processes facilitate optimum mineral reclamation and solids/product dewatering to low moistures with low cycle timesSolid/Liquid Separation Mineral ProcessingMagnetic Separation In Mineral Processing Wet magnetic separation is the commonly used technique for mineral processing Kelland, 1973, Oberteuffer, 1974 and is suitable for the recovery of fine ferro and diamagnetic mineral Shao et al, 1996Magnetic Separation In Mineral Processing

Mineral Processing and Metallurgical Testing

SRC’s Mineral Processing team provides leading‐edge re, development and demonstration services for a variety of commodities and mineral processing technologies We help maximize your resource and improve productivity at every stage of the mining cycle, from exploration to closureMineral processing Mining Mineral processing Solvay’s reagent portfolio includes offerings designed for the recovery of precious and base metals, such as copper, molybdenum, gold, nickel, cobalt, platinum group metals and polymetallics We also offer products for various industrial minerals such as phosphateMineral processing SolvayPrinciples of physical and chemical mineral processing are discussed and science and engineering principles of mineral processing and their application emphasized Topics covered include mineralogy, size liberation, grade recovery, comminution circuits, flotation, magnetic separation, leaching, thickening and filtration, various unit processes METS 2 Day Mineral Processing Course METS Engineering

Home Ball Mills for Mining and Mineral Processing Industry

Who We Are Founded in 1987, ZJH is mainly focus on producing and supply the ore grinding equipment, mineral separation equipment and laboratory and pilot equipment for Mines and Mineral Processing Plants Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to reduce the operating cost ,to improve the A wellfunctioning separation processis an essential component of improving the profitability of mining operations With installations in over 100 countries worldwide, is at the forefront of developing separation technology that offers both maximized recovery and lower operating costsSeparation Fig 2 Mineral processing is a part of extractive metallurgy Mineral Processing, together with metallurgy, constitute extractive metallurgy (Fig 2) Extractive metallurgy is a wide branch of knowledge as it covers many raw materials and numerous methods of separation Mineral processing is sometimes divided into mechanical and physicochemicalMineral Processing dbcwrocpl

Solid/Liquid Separation Mineral Processing

Solid/Liquid Separation solutions from Multotec enable optimal dewatering and metals/product recovery in the international chemicals and mineral processing markets Our tailored Solid/Liquid Separation technologies and processes facilitate optimum mineral reclamation and solids/product dewatering to low moistures with low cycle timesmineral separation plant equipment for gold processing plant Process Plant Machinery New Used Based in the UK, Process Plant and Machinery Ltd (PPM Ltd) is widely recognised as the Premier International Supplier of Quality Used Refurbished Process Equipmentmineral separation plant equipment for gold processing plantMineral Processing Mineral Processing Flotation Mineral comminution and separation systems civil engineering vol ii mineral comminution and separation systems toshio inoue encyclopedia of life support systems eolss discussion is also extended to the treatment of the solid wastes and wastewater occurring from the mineral processing plants and Processing Plant Copper Mineral Separation

gravity mineral processing processing separation spiral

Mineral processing Wikipedia Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation Mineral The process led to better separation and concentration of iron ore and thus better production indices Case 3 —— Xinjiang 3,300t/d Iron Mineral Processing Plant Project Introduction: The Xinjiang 3,300t/d iron mineral processing plant was an upgrading projectHematite Separation Process Mineral Processing Plant The Shanxi 1,200t/d iron mineral processing plant was an EPC+M+O project Our Solution: Twostage closedcircuit crushing and screeningtwostage closedcircuit grinding and classificationmagnetic separation process of onestage roughing and threestage concentration concentrates and tailings filtering and dewateringMagnetic Separation Process Mineral Processing Plant

Mineral Processing Heavy Mineral Separation Jig Machine View

Mineral Processing Heavy Mineral Separation Jig Machine View We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentHMS and DMS are acronyms for Heavy (Dense) Medium Separation and is applied to the process of preconcentration of minerals – mainly the production of a high weight, low assay product, which may be rejected as waste In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals of different specific gravity Fluids of suitable density DenseHeavy Medium Separation HMS / DMS ProcessPrinciples of physical and chemical mineral processing are discussed and science and engineering principles of mineral processing and their application emphasized Topics covered include mineralogy, size liberation, grade recovery, comminution circuits, flotation, magnetic separation, leaching, thickening and filtration, various unit processes METS 2 Day Mineral Processing Course METS Engineering

Minerals processing Downer Corporate Site

Our Mineral Technologies business is the world leader in mineral separation and mineral processing solutions, as well as spiral technology We deliver innovative, cost effective process solutions for iron ore, mineral sands, silica sands, coal, chromite, gold, tin, tungsten, tantalum