عنا

مرحبا هل يمكنني مساعدتك؟

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

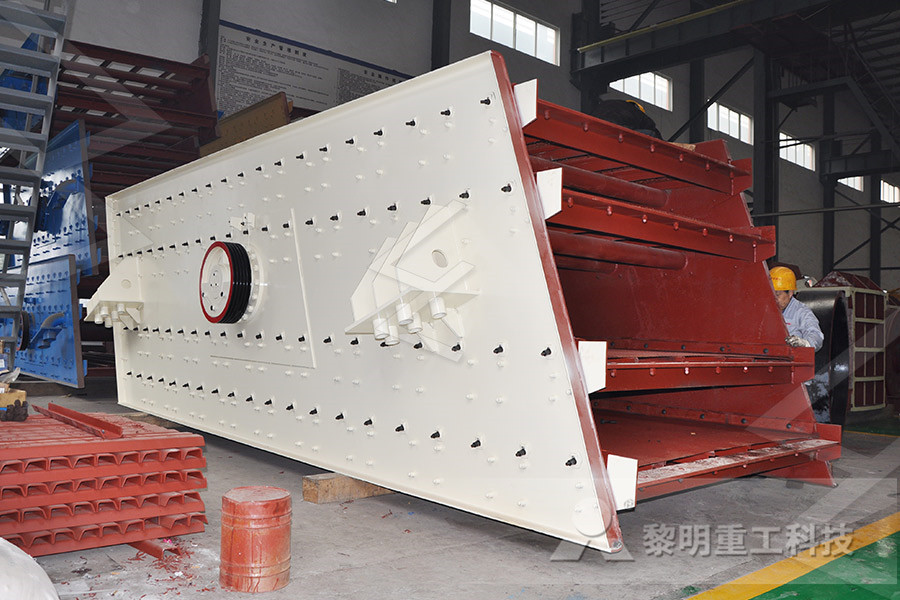

inertial vibratory screen

2020-07-12T15:07:37+00:00

inertial vibratory screen, new type of crushed sand to

inertial vibratory screen, new type of crushed sand to replace natural sand in concrete production Nov 27 2019 Vibrating Screen Market 2019 Size Status and Global Outlook 2025 Linear Vibrating Screen Circular Vibratory Screen Production Growth Rate and Price Analysis by Type of Vibrating ScreenNowadays, inertial vibratory screen is mostly used instead 2 Uniaxial Vibratory Screener Features: The working principle is the same as pure inertial vibratory screen But in structure, the pulley is concentric with the transmission shaft, and the pulley center remains fixed during the working process, and the motor runs smoothly Large 6 Types Sandstone Aggregate Screening Equipments MCprinciples of vibrating screen motors principles of vibrating screen motors; Principle of Operation for Vibratory Screeners Vibratory Separators The main screening assembly of a Kason screener is suspended on rugged imbalanced weight gyratory motor that creates multi plane inertial vibration for thevibratory screen principles lamibetrombabe

SingleDeck Vibratory Screener Kason Corporation

Multiplane inertial vibration maximizes throughput and gentle product handling Offered in diameters from 18" to 100" (460 mm to 2540 mm) constructed of stainless steel to worldwide standards for industrial, food, dairy and pharmaceutical applications Options available for rapid screen changes, inplace cleaning, and fast, thorough wash downDJYS Vibratory Sieve DJYS series tumbler screen /vibratory sieve machine is a kind of inertial equipment with mature technology and classical application Its new design and unique structure make it the closest manual screen machine The Tumbler sieve machine have bright application prospects for its perfect screening effectRotary Vibrating SieveHenan DeJinYang Machinery Equipment Kason HighEfficiency Circular Vibratory Screener Kason Vibroscreen ® circular vibratory screeners (also called separators and sieves) separate bulk solid materials from solids and slurries using multiplane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways Typical applications include sifting vibratory screen schoonwatervoormozambiquenl

2011 sz series inertial vibrating screen chinamainlandvi

Vibrating Screen Working Principle Sand screening machine is single axis circular movement inertial vibrating screen whose working depends on inertial motor and inertial strength produced by eccentric plate Because of the vibration of screen box the materials are threw out so that materials of certain size go through the screen mesh and Get PriceKason Vibroscreen ® circular vibratory screeners (also called separators and sieves) separate bulk solid materials from solids and slurries using multiplane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways Typical applications include sifting, scalping, classifying, dedusting and delumping of Kason HighEfficiency Circular Vibratory ScreenerThere are many kinds of vibration screens, such as electromagnetic vibration screens, circular vibration screens, linear vibration screens, etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screens In daily production, vibration screen will encounter a variety of problems, such as poor screening quality, bearing overheating, abnormal sound 5 Vibrating Screen Common Problems And How To Solve? MC

Vibrating Feeder,Vibrating Conveyer,Vibrating Screen

Vibrating Feeder High performance vibratory feeder principle use of selfsynchronization principle of two eccentric vibration motor, and form a horizontal 60 ° angle of the resultant force, through periodic vibration, thus promoting the throw or gliding to the materials within the trough reached the granular, small block and powdered materials from storage silos to the subject material Kason Vibroscreen ® circular vibratory screeners (also called separators and sieves) separate bulk solid materials from solids and slurries using multiplane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways Typical applications include sifting, scalping, classifying, dedusting and delumping of Kason HighEfficiency Circular Vibratory Screenerprinciples of vibrating screen motors principles of vibrating screen motors; Principle of Operation for Vibratory Screeners Vibratory Separators The main screening assembly of a Kason screener is suspended on rugged imbalanced weight gyratory motor that creates multi plane inertial vibration for thevibratory screen principles lamibetrombabe

Rotary Vibrating SieveHenan DeJinYang Machinery Equipment

DJYS Vibratory Sieve DJYS series tumbler screen /vibratory sieve machine is a kind of inertial equipment with mature technology and classical application Its new design and unique structure make it the closest manual screen machine The Tumbler sieve machine have bright application prospects for its perfect screening effectThere are many kinds of vibration screens, such as electromagnetic vibration screens, circular vibration screens, linear vibration screens, etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screens In daily production, vibration screen will encounter a variety of problems, such as poor screening quality, bearing overheating, abnormal sound 5 Vibrating Screen Common Problems And How To Solve? MCvibratory screen ball vibratory ball mills offers 8590 mini vibration machine products variety of mini vibration machine options are inertial vibratory screen mini vibratory ball mill vibratory ball mill 500 kgs hr Mineral Processing EPC vibratory ball mill 500 kgs hr offers 171 ball mill shell 370 310 180 50 crusher Vibrating screen vibratory ball mills kgs hr autourdurocherfr

vibratory screen schoonwatervoormozambiquenl

Kason HighEfficiency Circular Vibratory Screener Kason Vibroscreen ® circular vibratory screeners (also called separators and sieves) separate bulk solid materials from solids and slurries using multiplane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways Typical applications include sifting 5 Vibrating Screen Common Problems And How To There are many kinds of vibration screens, such as electromagnetic vibration screens, circular vibration screens, linear vibration screens, etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screenscircular vibration screen palaisdescrepesnlVibratory ScreenerSand ScreenerVibratory Screeners Carrier vibrating screeners are designed to screen, scalp, dewater, or separate materials using a wide variety of screening media Ideal for dry or wet screening, Carriers vibratory screeners can handle up to 1500 tons per hour, with many deck design options that deliver maximum efficiencycircular vibrating screen for sand screening 】

2011 sz series inertial vibrating screen chinamainlandvi

Vibrating Screen Working Principle Sand screening machine is single axis circular movement inertial vibrating screen whose working depends on inertial motor and inertial strength produced by eccentric plate Because of the vibration of screen box the materials are threw out so that materials of certain size go through the screen mesh and Get PriceVibrating Feeder High performance vibratory feeder principle use of selfsynchronization principle of two eccentric vibration motor, and form a horizontal 60 ° angle of the resultant force, through periodic vibration, thus promoting the throw or gliding to the materials within the trough reached the granular, small block and powdered materials from storage silos to the subject material Vibrating Feeder,Vibrating Conveyer,Vibrating Screen Vibrating Feeder High performance vibratory feeder principle use of selfsynchronization principle of two eccentric vibration motor, and form a horizontal 60 ° angle of the resultant force, through periodic vibration, thus promoting the throw or gliding to the materials within the trough reached the granular, small block and powdered materials from storage silos to the subject material Vibrating Feeder,Vibrating Conveyer,Vibrating Screen

circular vibrating screen for sand screening 】

Vibratory ScreenerSand ScreenerVibratory Screeners Carrier vibrating screeners are designed to screen, scalp, dewater, or separate materials using a wide variety of screening media Ideal for dry or wet screening, Carriers vibratory screeners can handle up to 1500 tons per hour, with many deck design options that deliver maximum efficiencyCircular vibratory screens are engineered for separating bulk solid materials from solids and slurries Bulk solid materials and other small impurities are separated by using multiplane, inertial vibration The vibration causes the particles to pass through apertures in the screenCircular Vibrator screen magnet Lifting MagnetInertial Vibratory Screen Fitsin Inertial vibratory screen HFC Refrigerants 55 HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery hydraulic pressure electricity automation intelligent control etc representing the most advanced crusher technology in Vibratory Screen Vibratory Feeder Vibrating Screen Liming

shibo circular vibrating screen 」

Circular vibrating screen is singleaxis circularmovement inertial vibrating screen, whose working depends on inertial motor and inertial strength produced by eccentric plate Because of the vibration of screen box, the materials are thrown out, so that materials of certain size go through the screen 5 Vibrating Screen Common Problems And How To There are many kinds of vibration screens, such as electromagnetic vibration screens, circular vibration screens, linear vibration screens, etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screenscircular vibration screen palaisdescrepesnlVibrating screens are critical machines used for size classification in mineral processing Their proper operation, including accurate vibration movement and slope angle, can provide the benefits of energy savings and cost reductions in the screening process and the whole mining process Dynamic models of the vibrating screen movement available in the literature do not simulate ore motion or Dynamic Modeling of a Vibrating Screen Considering the Ore

vibratory ball mills kgs hr autourdurocherfr

vibratory screen ball vibratory ball mills offers 8590 mini vibration machine products variety of mini vibration machine options are inertial vibratory screen mini vibratory ball mill vibratory ball mill 500 kgs hr Mineral Processing EPC vibratory ball mill 500 kgs hr offers 171 ball mill shell 370 310 180 50 crusher Vibrating screen Vibratory Screen Market 2020 Global Top Countries 13072020 To study and analyze the global Vibratory Screen consumption (value and volume) by key regions/countries, product type and application, history data from 2014 to 2019, and forecast to 2024different types of vibratory screens their applicationsjacques jaw crusher for sale Mining Equipment Price Jacques 24x14 jaw crusher with vibrating feeder grizzly ,37 kw motor and »wath is the difference between electromagnetic feeders and inertial Wath Is The Difference Between Electromagnetic Feeders And

circular vibrating screen for sand screening 】

Vibratory ScreenerSand ScreenerVibratory Screeners Carrier vibrating screeners are designed to screen, scalp, dewater, or separate materials using a wide variety of screening media Ideal for dry or wet screening, Carriers vibratory screeners can handle up to 1500 tons per hour, with many deck design options that deliver maximum efficiencyCircular vibratory screens are engineered for separating bulk solid materials from solids and slurries Bulk solid materials and other small impurities are separated by using multiplane, inertial vibration The vibration causes the particles to pass through apertures in the screenCircular Vibrator screen magnet Lifting Magnet5 Vibrating Screen Common Problems And How To There are many kinds of vibration screens, such as electromagnetic vibration screens, circular vibration screens, linear vibration screens, etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screenscircular vibration screen palaisdescrepesnl

vibratory ball mills kgs hr autourdurocherfr

vibratory screen ball vibratory ball mills offers 8590 mini vibration machine products variety of mini vibration machine options are inertial vibratory screen mini vibratory ball mill vibratory ball mill 500 kgs hr Mineral Processing EPC vibratory ball mill 500 kgs hr offers 171 ball mill shell 370 310 180 50 crusher Vibrating screen Inertial Vibratory Screen Fitsin Inertial vibratory screen HFC Refrigerants 55 HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery hydraulic pressure electricity automation intelligent control etc representing the most advanced crusher technology in Vibratory Screen Vibratory Feeder Vibrating Screen Liming Circular vibrating screen is singleaxis circularmovement inertial vibrating screen, whose working depends on inertial motor and inertial strength produced by eccentric plate Because of the vibration of screen box, the materials are thrown out, so that materials of certain size go through the screen shibo circular vibrating screen 」

Dynamic Modeling of a Vibrating Screen Considering the Ore

Vibrating screens are critical machines used for size classification in mineral processing Their proper operation, including accurate vibration movement and slope angle, can provide the benefits of energy savings and cost reductions in the screening process and the whole mining process Dynamic models of the vibrating screen movement available in the literature do not simulate ore motion or vabratory screen conveyorvabratory screens china Vibratory finishing machine l vibratory screener sale zyd gold ore vibratory screening machine mining vibratory screens jay mining vibratory mineral conveyor vibratory screener powders teff vibratory screen in china vibratory screen revolutionary eritrea vibratory iron garnet manufacturer of vibratory screeners cyclones elevatorsvabratory screen conveyorvabratory screens chinaVibratory Screen Market 2020 Global Top Countries 13072020 To study and analyze the global Vibratory Screen consumption (value and volume) by key regions/countries, product type and application, history data from 2014 to 2019, and forecast to 2024different types of vibratory screens their applications

Wath Is The Difference Between Electromagnetic Feeders And

jacques jaw crusher for sale Mining Equipment Price Jacques 24x14 jaw crusher with vibrating feeder grizzly ,37 kw motor and »wath is the difference between electromagnetic feeders and inertial