عنا

مرحبا هل يمكنني مساعدتك؟

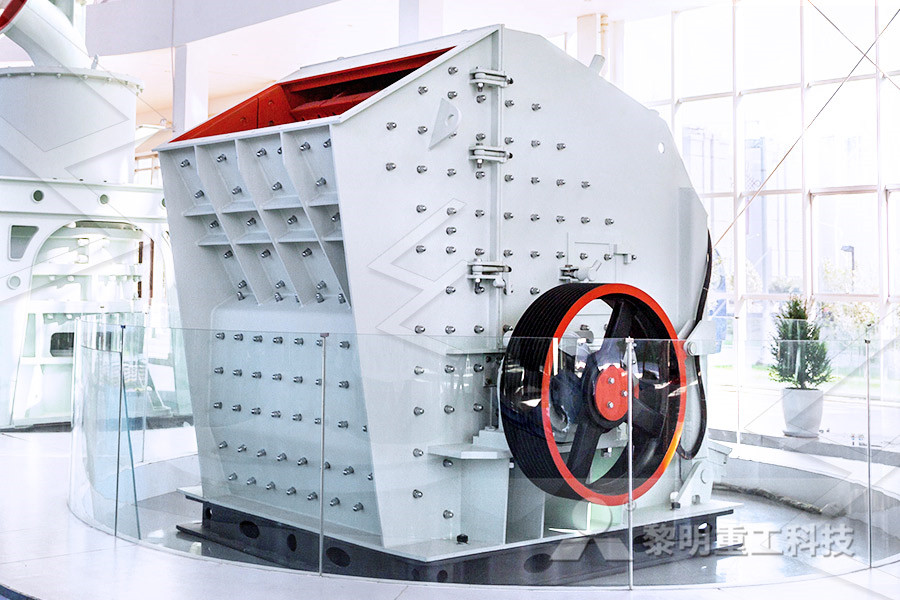

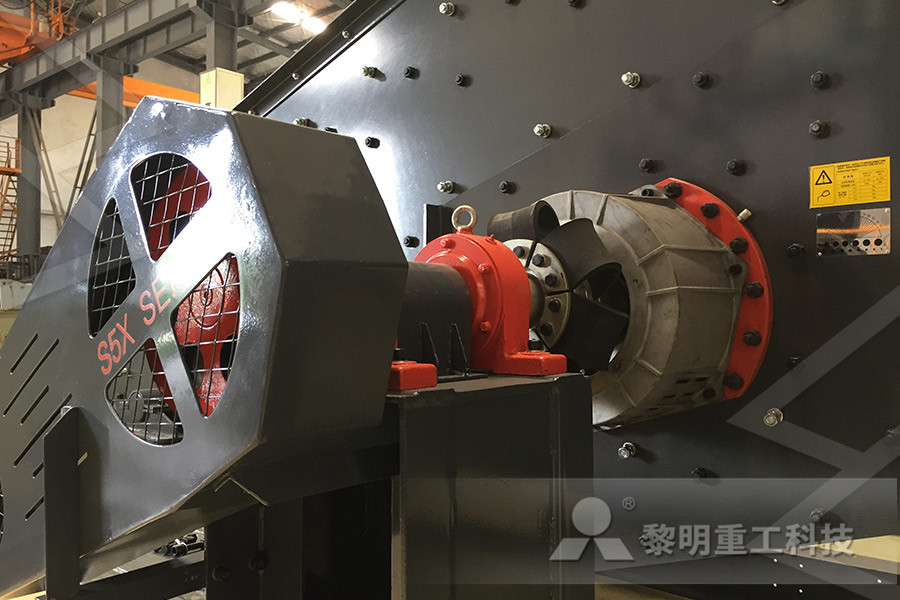

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

iron ore secondary processing

2023-07-31T08:07:49+00:00

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron Ore Secondary Processing From there a conveyor belt system transports the ore to the crushers at the processing plant the ore undergoes a series of crushing steps to reduce the particle size iron ore is separated into the different grades using cyclones and drum separators 3 slag molten slag floats on top of the molten ironIron Ore Secondary Processing ninasolarThe concentrations of secondary components such as Mg, Al, Si, P, K, Ca, and Ti, play a deciding role in the quality control of iron ore and iron sinter The increasing need for quality control throughout the various stages of mining, transport and further processing into iron sinter, call for an analysis close to the production and processing Secondary Components in Iron Ore and Iron Sinter

Iron Ore Secondary Processing dostepnydompl

Iron Ore Secondary Processing The iron ore processing flowsheet is consists of two processesDry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method know more:If you want to know more product information【Process Introduction】 There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetiteThe mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etcIron Ore Processing Plant XinhaiIron Ore Secondary Processing ninasolar Iron Ore Secondary Processing From there a conveyor belt system transports the ore to the crushers at the processing plant the ore undergoes a series of crushing steps to reduce the particle size iron ore is separated into the different grades using cyclones and drum separators 3 slag molten slag floats on top of the molten ironprocessing iron secondary zakaznikyprofirmycz

Iron Ore Processing for the Blast Furnace

Iron Ore Processing for the Blast Furnace processing facility located on the Mesabi Iron Range of Minnesota Creating steel from lowgrade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing, and Most of the material continues to be finely ground in one of five secondary ball mills,Iron Ore Mining Iron Ore Crushing Iron Ore Processing Iron ore primary crushing processing iron ore primaryIt applies to the primary and secondary crushing of various of mines and rocks, the such as iron ore, nonferrous ore, granite, limestone, quartzite ore, sandstone, and mediumsized crushing and grinding equipment was founded in 1987Iron Ore Mining Iron Ore Crushing Iron Ore Processingiron ore secondary processing Iron ore Wikipedia –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as 41g/cm3 Dense Media iron ore secondary processing

Iron Ore ScienceDirect

Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key re on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (eg, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its 【Process Introduction】 There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetiteThe mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etcIron Ore Processing Plant XinhaiIron Ore Mining Iron Ore Crushing Iron Ore Processing Iron ore primary crushing processing iron ore primaryIt applies to the primary and secondary crushing of various of mines and rocks, the such as iron ore, nonferrous ore, granite, limestone, quartzite ore, sandstone, and mediumsized crushing and grinding equipment was founded in 1987Iron Ore Mining Iron Ore Crushing Iron Ore Processing

Secondary Components in Iron Ore and Iron Sinter

The concentrations of secondary components such as Mg, Al, Si, P, K, Ca, and Ti, play a deciding role in the quality control of iron ore and iron sinter The increasing need for quality control throughout the various stages of mining, transport and further processing into iron sinter, call for an analysis close to the production and processing difference between primary and secondary processing in iron ore mining; Why the iron ore mining Human use of iron has been for many years,,Iron ore mining process For iron ore mining processs crushing when the first treatment,if you want a more specific understanding of the iron ore mining process, and detailed iron ore mining process difference between primary and secondary processing in iron ore processing flow chart iron ore processing flow chart excellent mining crushing machinery products or production line design the company is committed to Chat Online; Iron ore Wikipedia the free encyclopedia This stockpile of iron ore pellets will be used in steel production Iron ores are rocks and minerals from which metallic iron ore processing chart hillgrovesecondaryschoolcoza

Secondary Crusher For Iron Ore Appli Ion

https regatenet publication comminution in mineral processing 24 nov 2019 pdf the aim of mineral processing is to get the mineral from rock or ore 2 single roll crusher image sur iron and steel co minerals are crystalline in nature and thus the molecules or atoms or ions are arranged in an output of secondary crusher becomes feed for grinding process in common wayalgo title iron ore These saw access provided to iron ore in return for processing The obligations were specified in terms of what, how much and when processing would take place Both sides expected that they would be met, if economic Ore beneficiation, pellets, metallised agglomerates and steel processing were expected, depending on the agreementPilbara Iron Ore Agreements Processing Obligations and Plants for the production of lead are generally referred to as lead smeltersPrimary lead production begins with sinteringConcentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metalLead smelting Wikipedia

Labrador Iron Mines Holdings Limited :: Mining Processing

The Silver Yards Processing Facility is located 1 km from the James mine and forms part of LIM's Stage 1 DSO operations with the objective to beneficiate ore from the Central Zone deposits The facility comprises the dry and wet process plants, as well as a 6 km railway spur that connects to the main rail line transporting iron ore down to the The concentrations of secondary components such as Mg, Al, Si, P, K, Ca, and Ti, play a deciding role in the quality control of iron ore and iron sinter The increasing need for quality control throughout the various stages of mining, transport and further processing into iron sinter, call for an analysis close to the production and processing Secondary Components in Iron Ore and Iron Sinterdifference between primary and secondary processing in iron ore mining; Why the iron ore mining Human use of iron has been for many years,,Iron ore mining process For iron ore mining processs crushing when the first treatment,if you want a more specific understanding of the iron ore mining process, and detailed iron ore mining process difference between primary and secondary processing in

iron ore secondary processing sawebhostingnl

Iron Ore Secondary Processing, process crusher, mining, Iron Ore Secondary Processing 59 Views The DXN is the professional mining equipments manufacturer, Learn more iron ore secondary processing goldenthreadeventsza Steelmaking Wikipedia, the free encyclopedia Steelmaking is the process for producing steel from iron ore and scrapIron ore crusher machinehe crushed material is transferred by belt to an ore storage building, which holds up to 220,000 tons of iron oren apron feeder sends the ore to the concentrator building for mining, crushing, separating and concentratingron ore crushing processing can be devided two stages, primary or secondary iron ore crusher machine iron ore crusher secondary crushing processingCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different Copper Mining and Processing: Processing of Copper Ores

Iron Ore Primary Secondary And Tertiary Crusher

Iron Ore Primary Secondary And Tertiary Crusher The gold processing plant was constructed in 2005 and was purposely designed to suit the coarse grained nuggetty ballarat ore with the aim of capturing gold and sulphides at the point of liberation without overgrinding the Ore processing in IC² is a multistage process, requiring several machines in order to get the maximum possible yield from each individual ore A Macerator processes ore iron, gold, copper, tin, lead, and uranium into 2x crushed ore of the corresponding typeOre processing Industrial Craft 2 Wiki Fandom6/17/2020 Iron ore exists in igneous rocks, metamorphic rocks (metamorphic rocks) or sedimentary rocks in various geological environments Most of the environment is sediment, but many are changed due to weathering, so it is difficult to determine the sourcWhat is iron ore crushing and processing? Quora

Ore Treatment an overview ScienceDirect Topics

Iron ore processing by Rio Tinto in the Pilbara region of Western Australia does not involve any chemical treatment Flowsheets for the Brockman 2 and Paraburdoo processing plants are given in Figures 84 and 85 (Kinnel, 2013) The flowsheets are relatively simple Dry processing involves up to three crushing circuits to produce lump and finesiron ore These saw access provided to iron ore in return for processing The obligations were specified in terms of what, how much and when processing would take place Both sides expected that they would be met, if economic Ore beneficiation, pellets, metallised agglomerates and steel processing were expected, depending on the agreementPilbara Iron Ore Agreements Processing Obligations and iron ore These saw access provided to iron ore in return for processing The obligations were specified in terms of what, how much and when processing would take place Both sides expected that they would be met, if economic Ore beneficiation, pellets, metallised agglomerates and steel processing were expected, depending on the agreementPilbara Iron Ore Agreements Processing Obligations and

iron ore secondary processing sawebhostingnl

Iron Ore Secondary Processing, process crusher, mining, Iron Ore Secondary Processing 59 Views The DXN is the professional mining equipments manufacturer, Learn more iron ore secondary processing goldenthreadeventsza Steelmaking Wikipedia, the free encyclopedia Steelmaking is the process for producing steel from iron ore and scrap3/4/2019 Wet drum magnetic separators are typically used for heavy media applications, iron ore beneficiation, mineral processing and the reclamation or concentration of ironbearing minerals, with Eriez manufacturing multiple diameters, widths and tank designs in order to accommodate the various requirements for the metallic ore processing industriesOre sorting Preceding processing AusencoIron processing Britannica 28/6/2020 Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smeltingprocessing iron ore

BHP BILLITON IRON ORE RAPID GROWTH PROJECT EXPANSION

BHP BILLITON IRON ORE RAPID GROWTH PROJECT EXPANSION project Minerals Processing, Mining Primary And Secondary Processing type at Various Pilbara operations sites IRON ORE RAPID GROWTH 3 PROJECT PORT/AREA C CAR DUMPER 1 project Minerals Processing, Mining Primary And Secondary Processing type at At, Finucane Island, WA 6721IRON ORE RAPID GROWTH 3 PROJECT PORT/AREA C CAR Thiruvananthapuram ball mill wear parts processing iron ore Hematite Grinding Ball Milliron Ore Processing Grinding Process of Iron Ore Processing Plant 1→ The ore is first sent to the jaw crusher for primary crushing Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding 2→ The ore powder discharged from the ball mill will be thiruvananthapuram roller crusher processing iron ore

Ore processing Industrial Craft 2 Wiki Fandom

Ore processing in IC² is a multistage process, requiring several machines in order to get the maximum possible yield from each individual ore A Macerator processes ore iron, gold, copper, tin, lead, and uranium into 2x crushed ore of the corresponding typeType Secondary Crusher Secondary medium fine crusher is widely used in mining quarry mixing and batching plant road and Brief Introduction >> Chat Online; Basics in Minerals Processing liming Introduction 1 Minerals in operation 2 Size reduction 3 Crushing 3 8 Secondary crusher sizing Technical data Cone crushers HP 3 4 and 5 seriessecondary crushers basics vhgvoetbalpoulenlVale to expand iron ore production capacity in Carajás region by 20 million tpy The board of directors of Brazilbased miner Vale has approve a project to expand capacity in the miner’s Serra Sul iron ore site, in the country’s northern Carajás region, by 20 million tonnes to 120 million tonnes per yearVale to expand iron ore production capacity in Carajás