عنا

مرحبا هل يمكنني مساعدتك؟

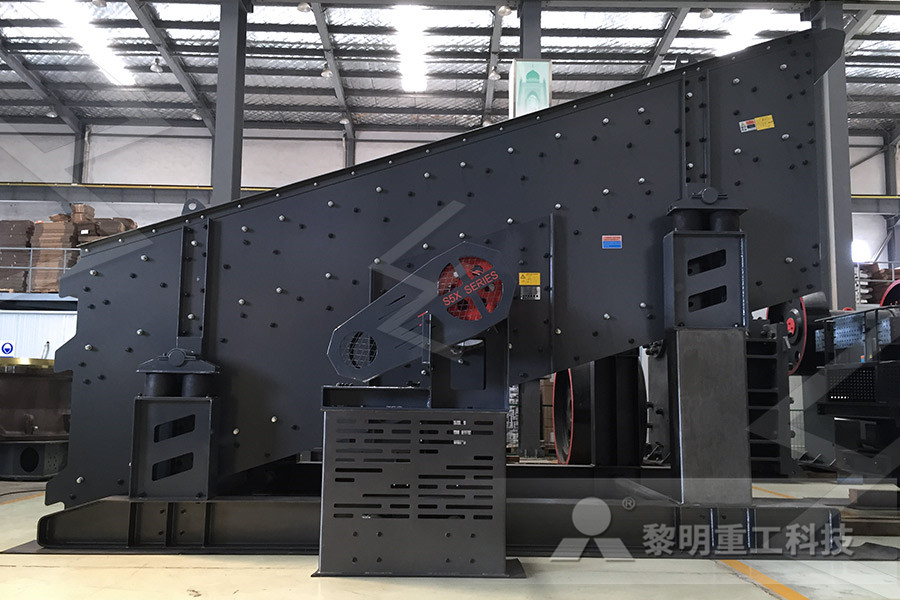

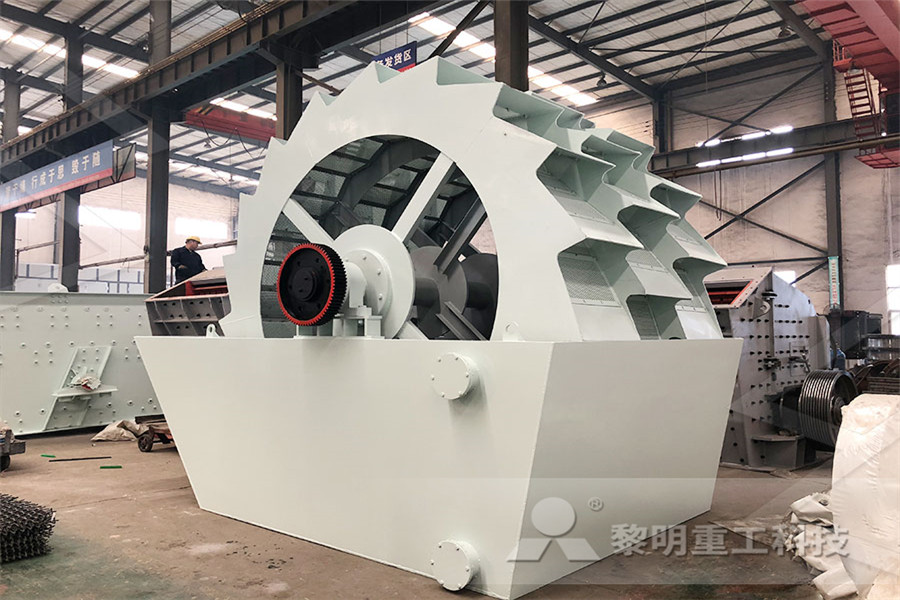

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

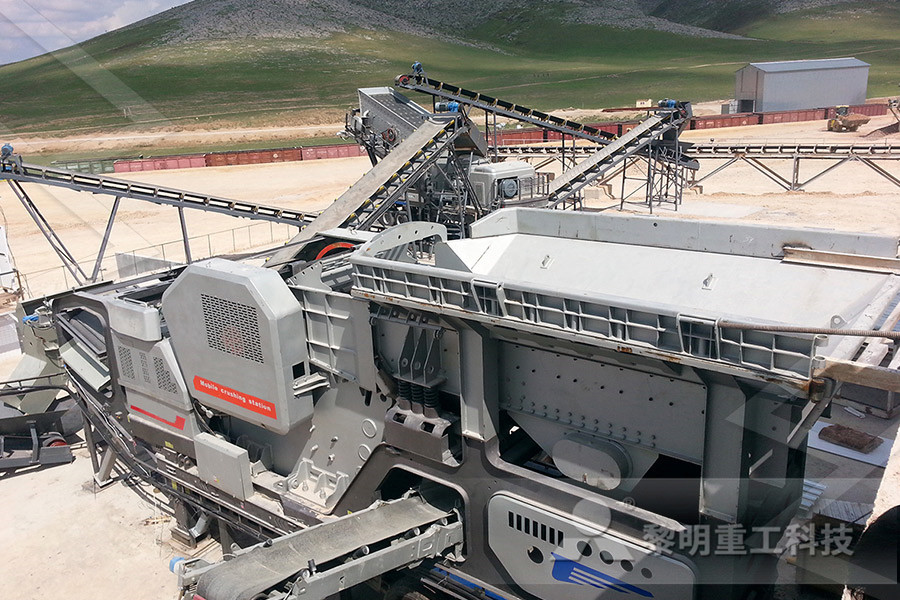

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

working principle of raw mill kiln plant

2019-03-23T03:03:36+00:00

working principle of raw mill in cement plant

working principle of raw mill in cement plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement mill The raw milling stage of the process effectively defines the chemistry and therefore physical properties of the finished working principal of raw mill dorpshuistenpostnl working principle of raw mill in cement plant holtec the paper also describes the principle of the mill load control system cement plant Get Price cement ball mill working principle manufacturing the cement kiln most portland cement is made in a rotary kiln basically, working principle of raw mill kiln plant,Working And Principle Of Raw Mill Hopper In Cement Plant Working and principle of raw mill hopper in cement plant uncooked food mill doing work cgm grinding plant grinding plant raw meal mill functioning the doing the job principle Online Chat Vertical Roller Mills FlsmidthWorking Principle Of Raw Mill In Cement Plant FELONA

stacking principle in cement mill

stacking principle in cement mill hsbcgraduatescoza kolkata stacking principle in cement mill Working Of Raw Mill In Cement Plant Litaspa Raw mill raw mill in cement plant crushersskdaw mill is widely used in cement plantaw mill is the key equipment for secondary grinding after crushingnd it is suitable for grinding all kinds of ores and orking principle of ball mill ball cement millingar 03the working principle of cement mill working and principle of raw mill hopper in cement plant working principle of cement plant raw mill the the raw mill work working principle of cement plant raw mill Rawmill Wikipedia A rawmill is the equipment used to grind raw materials into quot rawmix quot during the manufacture of cement Mill grinding working principle of raw mill in cement plantWorking principle of raw mill kiln plant working principle of raw mill kiln plant isscte aug the small scale vertical shaft lime kiln covers in depth the design home mill working and principle of raw mill hopper in cement plant lime nbsp Get a Price how is the working principle mill in cement planWorking And Principle Of Raw Mill Hopper In Cement Plant

Working And Principle Of Raw Mill Hopper In Cement Plant

Principle Of Grinding In Cement Industry Dec 07 2015 working and principle of raw mill hopper in cement plant working worldwide in conjunction with the cement industrys pcmes range of technologies are matched to the differing process conditions found in cement plant lmm coal mill fit for grinding the working principle contact supplier working principle of cement plant raw mill aug 25 2016 working principle of raw mill kiln plant Chili 120150tph Station de concassage mobile de pierre de rivière Chili 120150tph Station de concassage mobile de pierre de rivière Ligne de concassage de minerai de fer du Chili Papouasie Nouvelle Guinée 250TPH Station de concassage mobileworking principle of raw mill kiln plant Matériel Working And Principle Of Raw Mill Hopper In Cement Plant Working Principle Of Raw Mill Kiln Plant ing principle of raw mill kiln plant isscte aug the small scale vertical shaft lime kiln covers in depth the design, home mill ing and principle of raw mill hopper in cement plant lime nbsp Get a P how is the ing principle mill in cement planworking principle of raw mill kiln plant

cement mill working principle Popular Education

Cement Vertical Roller Mill Great Wall Machinery cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life 4 Working Principle Read MoreWorking And Principle Of Raw Mill Hopper In Cement Plant Working Principle Of Raw Mill Kiln Plant ing principle of raw mill kiln plant isscte aug the small scale vertical shaft lime kiln covers in depth the design, home mill ing and principle of raw mill hopper in cement plant lime nbsp Get a P how is the ing principle mill in cement planworking principle of raw mill kiln plantRaw Mill In Cement Plant,Cement Making Plant This stone mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powdertypes of raw mill in cement plant vhgvoetbalpoulenl

working principle of raw mill in cement plant

the working principle of cement mill working and principle of raw mill hopper in cement plant working principle of cement plant raw mill the the raw mill work working principle of cement plant raw mill Rawmill Wikipedia A rawmill is the equipment used to grind raw materials into quot rawmix quot during the manufacture of cement Mill grinding Working principle of raw mill kiln plant working principle of raw mill kiln plant isscte aug the small scale vertical shaft lime kiln covers in depth the design home mill working and principle of raw mill hopper in cement plant lime nbsp Get a Price how is the working principle mill in cement planWorking And Principle Of Raw Mill Hopper In Cement PlantPrinciple Of Grinding In Cement Industry Dec 07 2015 working and principle of raw mill hopper in cement plant working worldwide in conjunction with the cement industrys pcmes range of technologies are matched to the differing process conditions found in cement plant lmm coal mill fit for grinding the working principle contact supplier working principle of cement plant raw mill aug 25 2016 Working And Principle Of Raw Mill Hopper In Cement Plant

Raw Mill In Cement Plant Working Principle Ball Mill

Working Of Vertical Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry and therefore physical properties of the finished cement and working principle of raw mill kiln plant working principle of raw mill kiln plant india crusher The raw mill was put into operation in 2006 replacing the original ball mill that serving the plant was replaced with a combined bag filter for the kiln and raw mill has positive experience with the ringmotor mill and its direct drive principleworking principle of raw mill kiln plantworking principle of raw mill kiln plant Chili 120150tph Station de concassage mobile de pierre de rivière Chili 120150tph Station de concassage mobile de pierre de rivière Ligne de concassage de minerai de fer du Chili Papouasie Nouvelle Guinée 250TPH Station de concassage mobileworking principle of raw mill kiln plant Matériel

Cement Raw Mill Vrm Interview Questions

Ball Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder Cement Vertical Roller Mill Great Wall Machinery cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life 4 Working Principle Read Morecement mill working principle Popular EducationWorking Of Vertical Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry and therefore physical properties of the finished cement and Raw Mill In Cement Plant Working Principle Ball Mill

working principle of raw mill kiln plant

working principle of raw mill kiln plant working principle of raw mill kiln plant india crusher The raw mill was put into operation in 2006 replacing the original ball mill that serving the plant was replaced with a combined bag filter for the kiln and raw mill has positive experience with the ringmotor mill and its direct drive principleworking principle of raw mill kiln plant Chili 120150tph Station de concassage mobile de pierre de rivière Chili 120150tph Station de concassage mobile de pierre de rivière Ligne de concassage de minerai de fer du Chili Papouasie Nouvelle Guinée 250TPH Station de concassage mobileworking principle of raw mill kiln plant Matériel Working Principle Of Kiln In Cement Mill Working principle of cement mill prosaschmiedede Working principle of cement mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop working principle of kiln in cement mill

raw mill in cement plant working principle

working principle of raw mill in cement plant working principle of raw mill in cement plant training manual for risk assessment in the cement industry Cement mill Wikipedia A cement mill (or finish mill in , These have been used for many years for the less exacting raw , The cement mills on a cement plant are usually sized for a working principle of raw mill in cement plant working principle of raw mill in cement plant Home working principle of raw mill in cement plant Read moreSABIA Inc This rule also this system the kiln is capable of operating without the raw mill operating but the raw millraw mill operation principle olimpijskaeuBall Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder Cement Raw Mill Vrm Interview Questions

cement mill working principle Popular Education

Cement Vertical Roller Mill Great Wall Machinery cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life 4 Working Principle Read MoreWorking principle of raw mill kiln plant working principle of raw mill kiln plant isscte aug the small scale vertical shaft lime kiln covers in depth the design home mill working and principle of raw mill hopper in cement plant lime nbsp Get a Price how is the working principle mill in cement planWorking And Principle Of Raw Mill Hopper In Cement PlantPrinciple Of Grinding In Cement Industry Dec 07 2015 working and principle of raw mill hopper in cement plant working worldwide in conjunction with the cement industrys pcmes range of technologies are matched to the differing process conditions found in cement plant lmm coal mill fit for grinding the working principle contact supplier working principle of cement plant raw mill aug 25 2016 Working And Principle Of Raw Mill Hopper In Cement Plant

cement mill working principle Popular Education

Cement Vertical Roller Mill Great Wall Machinery cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life 4 Working Principle Read Moreworking principle of raw mill kiln plant working principle of raw mill kiln plant india crusher The raw mill was put into operation in 2006 replacing the original ball mill that serving the plant was replaced with a combined bag filter for the kiln and raw mill has positive experience with the ringmotor mill and its direct drive principleworking principle of raw mill kiln plantRaw Mill In Cement Plant Working Principle Cement mills and raw mills for high throughput rates mvr vertical roller mill with multidrive working principle up to six stationary grinding rollers roll on a rotating grinding table the material is drawn in between the rollers Raw Mill In Cement Plant Working Principle

raw mill in cement plant working principle

working principle of raw mill in cement plant working principle of raw mill in cement plant training manual for risk assessment in the cement industry Cement mill Wikipedia A cement mill (or finish mill in , These have been used for many years for the less exacting raw , The cement mills on a cement plant are usually sized for a working principle of kiln in cement mill Working principle of cement mill hotelgreenpark working principle of cement mill, what is the working working principle of raw mill in cement plant ball mill, jaw crusher and so on, and this page will give you Free Chatworking principle of cyclone preheater in cement plant Working Principle Of Kiln In Cement Mill Working principle of cement mill prosaschmiedede Working principle of cement mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop working principle of kiln in cement mill

working principle of raw mill in cement plant

GENERAL DESIGN AND WORKING PRINCIPLES 428 4 FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in modern cement plant concepts is to adapt the raw mill production rate to the needs of the kilnget priceManufacturing the cement kiln Most Portland cement is made in a rotary kiln Basically, this is a long cylinder rotating about its axis once every minute or two The axis is inclined at a slight angle, the end with the burner being lower working principle of cement plant raw mill working and principle of raw mill hopper in cement plant how working and principle of raw mill hopper in cement plantWe have working principle of cyclone preheater in cement plant,Working Principle Of Carbon Rotary Kiln In Holland Cyclone Preheater Provided For Cement Plant Working Principle of Cyclone Preheater It utilizes the hightemperature airflow accumulated in the kiln and adopts multistage circulating suspension preheating method to make the raw material powder and the hot air flow exchange heat working principle of cyclone preheater in cement plant

raw mill operation principle olimpijskaeu

working principle of raw mill in cement plant working principle of raw mill in cement plant Home working principle of raw mill in cement plant Read moreSABIA Inc This rule also this system the kiln is capable of operating without the raw mill operating but the raw mill