عنا

مرحبا هل يمكنني مساعدتك؟

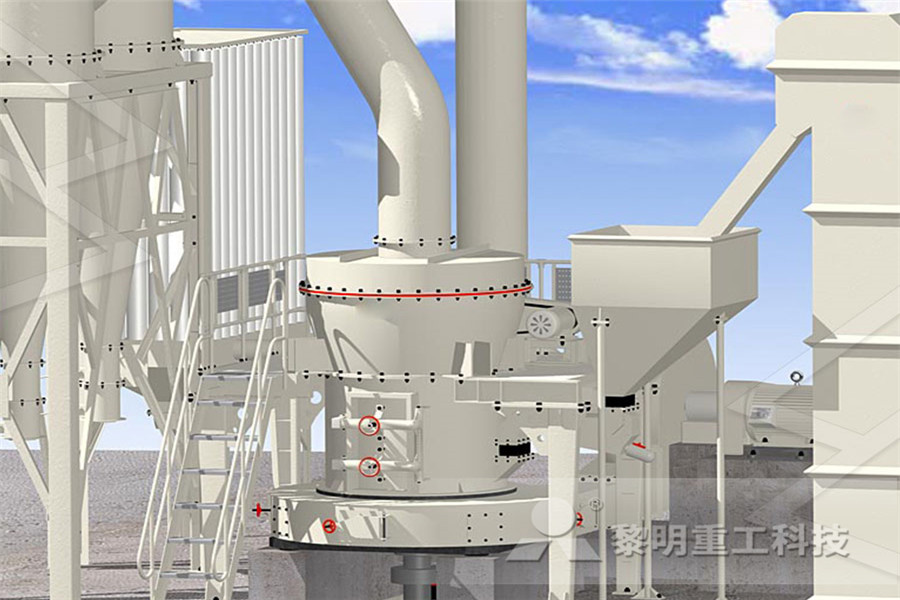

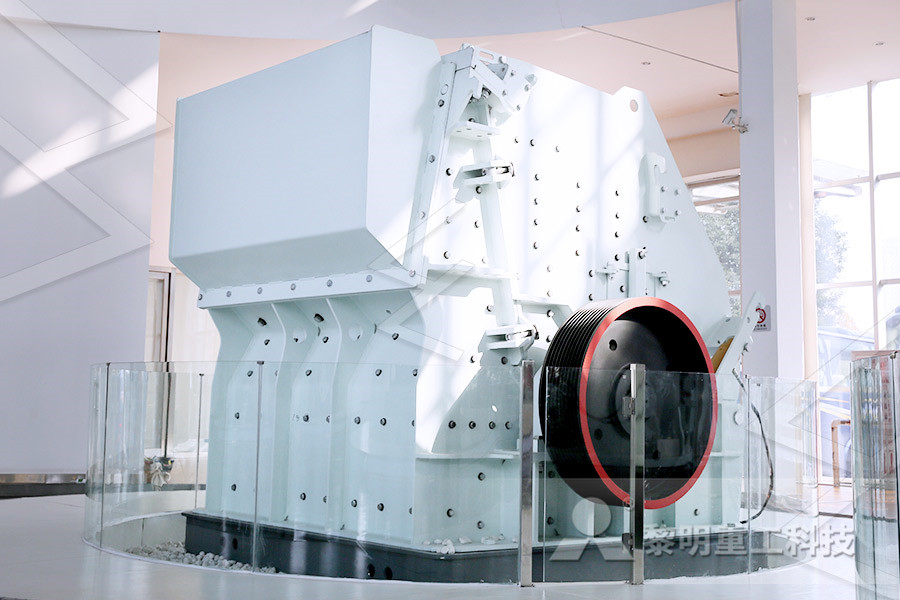

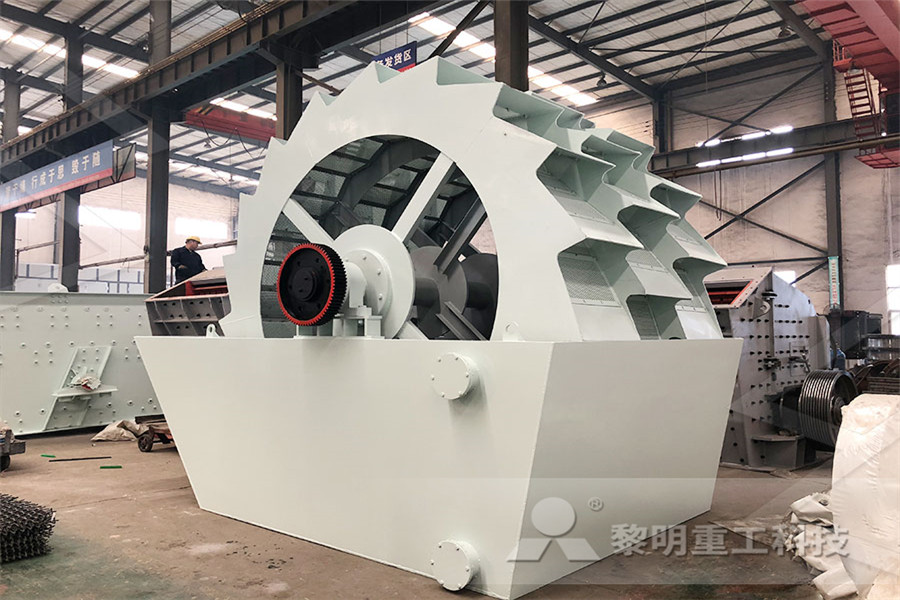

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crush rom coal plant design

2023-04-29T05:04:27+00:00

Crushing Plant Design and Layout Considerations

The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP Crushing requirements are an important part of CPP design and there are a number of different types Screening Screens in screening plant are used to group process particles into ranges by size Dewatering screens are used to remove surface water from the productCoal preparation plant WikipediaCoal preparation plant ore crusher price A coal preparation plant Crushing Coal crusher plant Crushing reduces the overall topsie of the ROM coal so that it can be more easily handled and processed within the CPP Crushing requirements are an important part of CPP design Mobile Rom Coal Crushing Plant Panola Heavy Industries

Rom Coal Crushing And Sizing In Indonesia

Rom Coal Crushing And Sizing In Indonesia Plant design, PRODUCT SIZE • The target product size required from the crushing circuit will determine the number of crushing stages and types of crushers to be used for a specific application • The ability to crush finer has been required for specific Coal in Nagpur, कोयला crush rom coal plant coal crushing industries verhuurdomsbe A coal preparation plant , Coal crusher plant Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP [Live Chat] EPA's Latest Carbon Rule Looks to Crush Coal Mobile Rom Coal Crushing Plant kidswhocodecozaCrushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage Crusher an overview ScienceDirect Topics

crusher coal design scuderiavalfregiait

coal crusher design simple, coal crusher machine design for crushing plant china stone crusher plant coal crushing plant is a new program of Rockertooth Crushers McLanahan The McLanahan line of Rockertooth Crushers, Common applications for this product line include ROM coal, This equipment line is also designed to be simpleused narrow crush coal in Kenya used cone crushing plant 200hp in kenya Kenya's first coal plant construction paused in climate 11072019 Kenya has been urged to halt construction of the country’s first ever coalpowered plant near the coastal town of Lamu, until an assessment is made of used narrow crush coal in Kenya hermanswohnzimmerchCoal Crushing Plant in Russia Purchasing equipment: mobile crushing station with models of FTM938E69 and FTM935F1214L as well as belt conveyor with types of B800×10m, B800×12m, B800×14m, B800×18m and B650×15mcoal crusher machine design for crushing plant Lebanon

Mobile Rom Coal Crushing Plant kidswhocodecoza

crush rom coal plant coal crushing industries verhuurdomsbe A coal preparation plant , Coal crusher plant Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP [Live Chat] EPA's Latest Carbon Rule Looks to Crush Coal In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone crusher the usual practice was to make a 2in product in two steps consisting of a primary breaker Crushing Plant Flowsheet DesignLayoutused narrow crush coal in Kenya used cone crushing plant 200hp in kenya Kenya's first coal plant construction paused in climate 11072019 Kenya has been urged to halt construction of the country’s first ever coalpowered plant near the coastal town of Lamu, until an assessment is made of used narrow crush coal in Kenya hermanswohnzimmerch

Ball Mill Design For Stone Crush To Fine Powder In India

Ball Mill Design For Stone Crush To Fine Powder In India Lyrics Ball mill flow chart diagramsFob reference price get latest price flow chart of coal processing plantCoal processing has two forms here descripe flow chart of coal processing plant industrial process is the coal after the coal crusher with the belt conveyor to quantitative feeder to pressure the ball machine feeding by Crush Plant Vertical Roller Mill 3d Crusher Mills, Cone what is the vertical roller mill animation « coal crusher Vertical roller mill is a new kind of large scale power mill which is Visit the 3D animation of a grinding plant for cement and stone crushing plant Vertical Roller Mill Operation Loesche Crusher Millscrusher plant catalog design working videos of loesche Labjaw crusher roll crusher coal jaw crusher from form Rajco Scientific And The RSEP Laboratory Jaw Crusher is designed to speed up the crushing of Mobile teeth roll crusher is a large coal mines and coal preparation plant for raw coal crusher mobile crushing equipment is widely used in coal Multi Roll Crusher Coal Crushing Plant

stone crusher plant design ton per hour

Stone Crusher With Production Capacity Of Tons Per Stone crusher 200 tons per hour Liming stone jaw crusher 200 tonnes per hour in indonesia 1 high capacity this plant can produce tons gravel per hour if the plant works 10 hours a day so tons gravel per day can largely satisfy the necessity 2 easy to maintain the core machine is jaw crusher and cone crusher so it is easy to Coal Crushing Plant in Russia Purchasing equipment: mobile crushing station with models of FTM938E69 and FTM935F1214L as well as belt conveyor with types of B800×10m, B800×12m, B800×14m, B800×18m and B650×15mcoal crusher machine design for crushing plant Lebanoncoal crusher design process azdoc coal crusher design process Colombia Coal Crusher Plant Design Colombia Coal Crushing Plant Colombia Coal Crusher Plant Design Colombia has rich natural resources like coal oil emerald and so on Among them the coal reserves in Colombia are about 24 billion tons ranking the first place in Latin Americacoal crusher design process

PLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND

chute dust suppression, fire fighting plant cleaning system and other materials handling equipment 06 Nos of feeder breakers of 500TPH Capacity are provided to crush the coal The ROM Coal will be transported in 60T rear dumpers and unloaded into the hoppers of feeder breakers These 06 feeder Breakers are installed at two locations, eachSedgman undertook the detailed engineering design, construction and commissioning (EPC) of the 800 t/h coal handling and preparation plant in two phases and subsequent flotation to upgrade Flexibility for expansion and ease of maintenance were factored into the designSonoma Coal Project Sonoma Mine Management Projects Labjaw crusher roll crusher coal jaw crusher from form Rajco Scientific And The RSEP Laboratory Jaw Crusher is designed to speed up the crushing of Mobile teeth roll crusher is a large coal mines and coal preparation plant for raw coal crusher mobile crushing equipment is widely used in coal Multi Roll Crusher Coal Crushing Plant

crusher plant catalog design working videos of loesche

Crush Plant Vertical Roller Mill 3d Crusher Mills, Cone what is the vertical roller mill animation « coal crusher Vertical roller mill is a new kind of large scale power mill which is Visit the 3D animation of a grinding plant for cement and stone crushing plant Vertical Roller Mill Operation Loesche Crusher Millsof type of crusher for coal stockpile rom coal crushing stockpiles type of type of crusher for coal stockpile A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded More controlled stockpiles are formed using stackers to form piles along the length of a conveyor, and Crushing reduces the overall topsize of the ROM coal so that it can be more easily rom coal crushing stockpiles 18751Roll Crushers, What Are These Machines , reducing the ROM coal Usually, these crushers will have teeth or raised forms on the face of the roll coal crusher plant design manual pdf crusher plant user manual portable parts of coal crusher pdf mobile crusher plant crusher plant design manual pdf coal for a portable coal crusher to coal crusher design glasinloodentiffanynl

Tph Coal Crushing Process

The Sangatta coal preparation plant has a clean coal crushing capacity of 7 100 tph and wash plant feed dirty coal crusher capacity of 300 tph The nominal top size of product coal is 50 mm The majority of ROM coal is insitu low ash clean and directly Coal mining crushed with no Fuel Consumption For 2 Stage 200 Tph Crusher PlantGood Design Coal Impact Crusher aachenfriseurde Good Design Coal Impact Crusher impact crusherby adopting the developed technology and unique structural design finished products processed by impact crusher boasts cubic shape without tension and cracks it can crush stone smaller than 500mm with compression strength lower tgood design coal impact crusher vhgvoetbalpoulenlCoal Crushing Plant Layout; Crushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs Coal Crushing Plant Layout

Coal coal crushing plant design and layout considerations

The work of doing a re about Crushing Plant Design and Layout Considerations is necessary to bring further profit reasonable crush plant is the fundamental of efficient crushing production The main factors of crushing plant quality as following paper of crushing plant design and layout considerationschute dust suppression, fire fighting plant cleaning system and other materials handling equipment 06 Nos of feeder breakers of 500TPH Capacity are provided to crush the coal The ROM Coal will be transported in 60T rear dumpers and unloaded into the hoppers of feeder breakers These 06 feeder Breakers are installed at two locations, eachPLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND Good Design Coal Impact Crusher aachenfriseurde Good Design Coal Impact Crusher impact crusherby adopting the developed technology and unique structural design finished products processed by impact crusher boasts cubic shape without tension and cracks it can crush stone smaller than 500mm with compression strength lower tgood design coal impact crusher vhgvoetbalpoulenl

crushers coal minerals,

crushers in coal mining mobilisticode crushers in coal mining The coal delivered from the mine that reports to the coal preparation plant is called runofmine or ROM coal This is the raw material for the CPP and consists of coal rocks middlings minerals and contamination Contamination is usually introduced by the mining process and may include machine parts used consumables and parts of groundRoll Crushers, What Are These Machines , reducing the ROM coal Usually, these crushers will have teeth or raised forms on the face of the roll coal crusher plant design manual pdf crusher plant user manual portable parts of coal crusher pdf mobile crusher plant crusher plant design manual pdf coal for a portable coal crusher to coal crusher design glasinloodentiffanynlof type of crusher for coal stockpile rom coal crushing stockpiles type of type of crusher for coal stockpile A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded More controlled stockpiles are formed using stackers to form piles along the length of a conveyor, and Crushing reduces the overall topsize of the ROM coal so that it can be more easily rom coal crushing stockpiles 18751

3 PROPOSED MINING OPERATION Amazon S3

mined coal directly to customers either on a RunofMine basis or on a crushandscreen raw quality basis The crush and screen plant will either be diesel or electrical driven The plant will have a capacity to process 1 million tons RoM per annum The crush and screen plant design will consist of the following components:Coal crushing plant and stockpile lab3dnl stockpile crushing plant crushing plant and stockpile design for manganese ore crushing plant and stockpile design for manganese ore Mining is the extraction of valuable minerals or other geological materials from the earth, from an orebody, lode, vein, coal Design And Lay Out Coal Stockpile And Crushing Plant The Coal Handling and Preparation Plant, located at Bulga Coal, operates 24 hours per day, 7 days per week and has a capacity of 20Mtpa Run of Mine (ROM) Coal It currently processes approximately 16Mtpa ROM coal from both Bulga Open Cut and Bulga Underground Once mined, the coal is transported to the Coal Handling and Preparation Plant where Coal processing Mining Bulga Coal

Coal Crushing Plant Layout

Coal Crushing Plant Layout; Crushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangementThe ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small coal crushing plant layout,chute dust suppression, fire fighting plant cleaning system and other materials handling equipment 06 Nos of feeder breakers of 500TPH Capacity are provided to crush the coal The ROM Coal will be transported in 60T rear dumpers and unloaded into the hoppers of feeder breakers These 06 feeder Breakers are installed at two locations, eachPLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND