عنا

مرحبا هل يمكنني مساعدتك؟

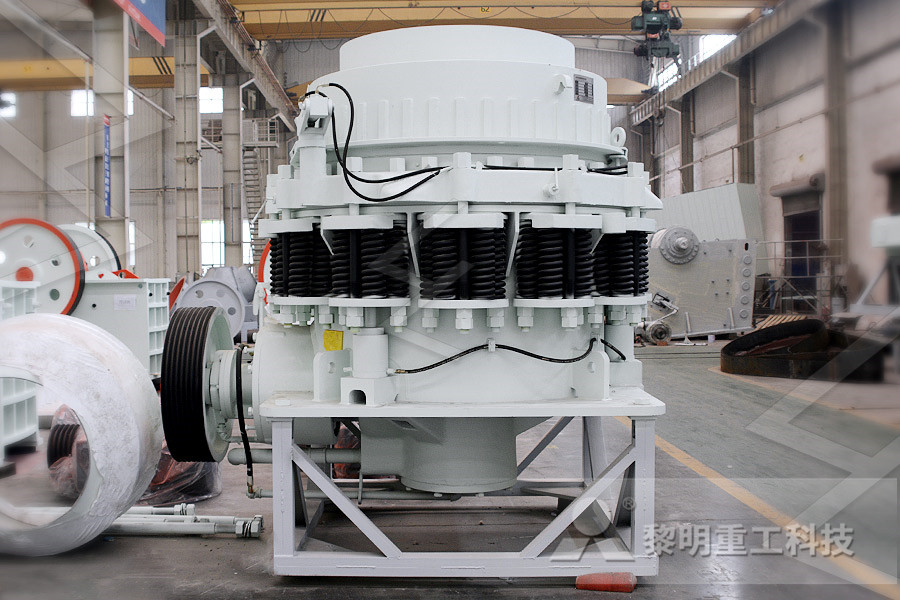

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

disadvantages of vertical coal mill in cement industry wiki

2020-05-29T00:05:31+00:00

Disadvantages Of Vertical Coal Mill In Cement Industry Wiki

how can a coal mill do work in cement parts of a vertical coal mill, vertical mill used in cement industry, coal grinding vertical mill supplier in USA, Nigeria, indiacement in vertical coal mill Gold Ore Crusher cement in vertical coal mill vertical dryer is aimed at the disadvantages current used in cement, chemical, metallurgic industry and so ondisadvantages of vertical coal mill in cement industry wikiCoal Mill Operation In Cement Coal Mill Operation In Cement Vertical roller millvrm and coal mill operation in cement factorySurender naik ramavathLoading unsubscribe from surender naik ramavathThermal power plant in hindi with advantages and disadvantagesDuration 637Learn eee 118,750 viewsVertical roller mill repair castolin eutecticBle experts having worked on more than 30vertical coal mill operation in cement industry

coal mill of cement indstri bbdeicolliit

What Is Coal Mill Of A Cement Industry Cement Mill Wikipedia A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsVertical coal mill in cement industry wiki Cement Grinding Vertical Roller Mills Versus Ball cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical ball race coal mill arrangementvertical mill for cement grinding in india Vertical roller mill in cement industry india Cement Grinding Vertical Roller Mills Versus Ball cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still cement in a vertical roller mill the layout as shown in Figure 7 is prepared withprinciples of grinding in a cement industry, hammer mill

Process Fans Used in Cement Industry Reitzindia

In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning These fans help in effective burning of coal inside the mill For a large clinker line there are usually 2 or 3 cement millscement in vertical coal mill Gold Ore Crusher cement in vertical coal mill vertical dryer is aimed at the disadvantages current used in cement, chemical, metallurgic industry and so ondisadvantages of vertical coal mill in cement industry wikiA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

vertical ball race coal mill arrangement

Vertical coal mill in cement industry wiki Cement Grinding Vertical Roller Mills Versus Ball cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical mill for cement grinding in india Vertical roller mill in cement industry india Cement Grinding Vertical Roller Mills Versus Ball cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still cement in a vertical roller mill the layout as shown in Figure 7 is prepared withprinciples of grinding in a cement industry, hammer mill In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning These fans help in effective burning of coal inside the mill For a large clinker line there are usually 2 or 3 cement millsProcess Fans Used in Cement Industry Reitzindia

process flow diagrame of cement grinding mill in vrm process

Vertical Roller Mill Operation,Vertical Grinding Mill At the beginning of the 90's the mill in cement grinding and have new progress, there The basic process of the roller mill is the final grinding, but in order to Fine powder with an air flow mill, collected in the dust collecting apparatus system, What are the safety hazards of replacing coal mill liners in cement plants Sep 13, 2019 Cement factory replacement of wearresistant parts, must comply with safety regulations to operate, generally require maintenance personnel with certain work experience to be presentWhat are the safety hazards of replacing coal mill liners Product quality and compliance with dust emission limits are core requirements for dedusting in the cement, gypsum and lime industry The choice of filter media is of paramount importance in cement kilns where there are high NOx levels due to high combustion temperatures Raw coal: 15: Vertical coal grinding mill: 16: Bag filter for coal Filter Bag for Cement Plant – Filmedia Home

Plant engineering solutions for any mission Loesche

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industriescement in vertical coal mill Gold Ore Crusher cement in vertical coal mill vertical dryer is aimed at the disadvantages current used in cement, chemical, metallurgic industry and so ondisadvantages of vertical coal mill in cement industry wikiA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

Process Fans Used in Cement Industry Reitzindia

In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning These fans help in effective burning of coal inside the mill For a large clinker line there are usually 2 or 3 cement millsA ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Ball Mill: Operating principles, components, Uses Vertical Roller Mill Operation,Vertical Grinding Mill At the beginning of the 90's the mill in cement grinding and have new progress, there The basic process of the roller mill is the final grinding, but in order to Fine powder with an air flow mill, collected in the dust collecting apparatus system, process flow diagrame of cement grinding mill in vrm process

The Disadvantages of Fly Ash in Concrete Hunker

Fly ash is a byproduct from coalfired power plants that is frequently used as an admixture in concrete to replace a portion of the Portland cement Using fly ash in concrete is environmentally beneficial because it reduces the Portland cement (a major contributor of CO2) required in concreteWhat are the safety hazards of replacing coal mill liners in cement plants Sep 13, 2019 Cement factory replacement of wearresistant parts, must comply with safety regulations to operate, generally require maintenance personnel with certain work experience to be presentWhat are the safety hazards of replacing coal mill liners Product quality and compliance with dust emission limits are core requirements for dedusting in the cement, gypsum and lime industry The choice of filter media is of paramount importance in cement kilns where there are high NOx levels due to high combustion temperatures Raw coal: 15: Vertical coal grinding mill: 16: Bag filter for coal Filter Bag for Cement Plant – Filmedia Home

Plant engineering solutions for any mission Loesche

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industriesWet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmBall Mill,Grinding Ball Mill Equipment For Sale, Ball Mill Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industriesPlant engineering solutions for any mission Loesche

Process Fans Used in Cement Industry

2/23/2016 Coal mill fans: In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning These fans help in effective burning of coal inside the mill For a large clinker line there are usually 2 or 3 cement mills 86/1/2017 Manufacturing of cement (key ingredient used for the production of concrete) is a major source of greenhouse gas emissions (Imbabi et al, 2012) The use of supplementary cementitious materials (s) to offset a portion of the cement in concrete is a promising method for reducing the environmental impact from the industryWaste glass powder as partial replacement of cement for Fly ash is a byproduct from coalfired power plants that is frequently used as an admixture in concrete to replace a portion of the Portland cement Using fly ash in concrete is environmentally beneficial because it reduces the Portland cement (a major contributor of CO2) required in concreteThe Disadvantages of Fly Ash in Concrete Hunker

disadvantage from ball mill cement mill – Grinding Mill China

disadvantages of vertical coal mill in cement industry wiki 3 CEMENT MANUFACTURING TECHNOLOGIES plant Heat recovery Power generation plant C2 Vertical roller mill Conventionally, a ball mill and a classifier were used » Learn More advantages and disadvantages of ball mill China's cement industry, which produced 1,388 million metric tons (Mt) of cement in 2008, accounts for almost half of the world's total cement production Nearly 40% of China's cement production is from relatively obsolete vertical shaft kiln (VSK) cement plants, with the remainder from more modern rotary kiln cement plants, including plants Analysis of EnergyEfficiency Opportunities for the Cement In the diagram above of a precalciner kiln, raw meal passes down the preheater tower while hot gases rise up, heating the raw meal At 'A,' the raw meal largely decarbonates; at 'B,' the temperature is 1000 C 1200 C and intermediate compounds are forming and at 'C,' the burning zone, clinker nodules and the final clinker minerals formThe cement kiln

Plants and Machinery Maha Cement

Grinding Unit at Vizag was established in 2009 with capacity of 15 MTPA and upgraded to 20 MTPA in 2012 The Plant is endowed with advanced technology of Vertical Roller Mill for slag grinding supplied by Loesche, Germany and Ball Mill for grinding OPC PPC from Humboldt Wedag, Germany11/18/2010 Cement production is an energyintensive process consuming thermal energy of the order of 33 GJ/tonne of clinker produced Electrical energy consumption is about 90 – 120 kWh/tonne of cement (Giddings, et al, 2000; European Commission [EC] 2001) Historically, the primary fuel used in cement industry is coalAlternative Fuels in Cement Manufacturing IntechOpenEnergy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases thWhat is a ball mill? What are its uses and advantages? Quora