عنا

مرحبا هل يمكنني مساعدتك؟

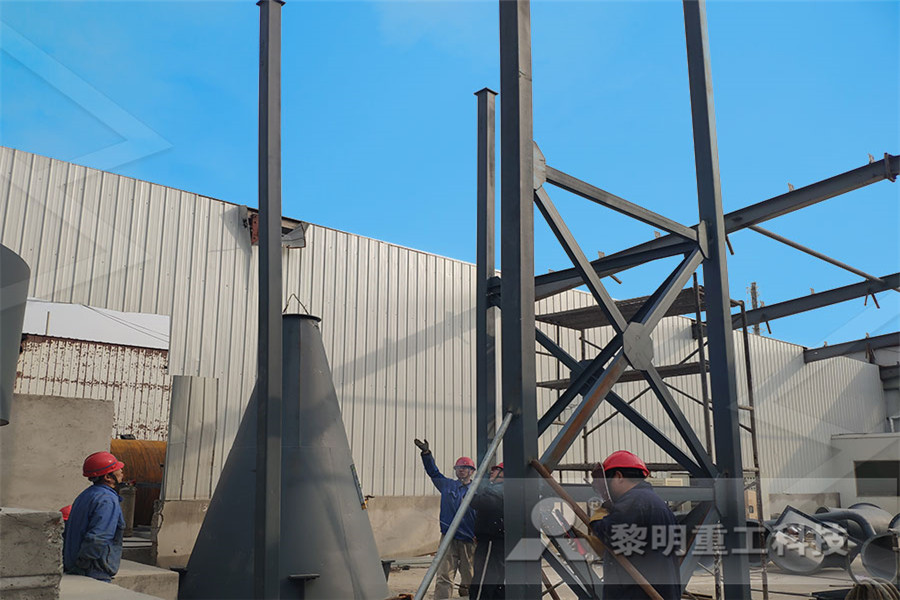

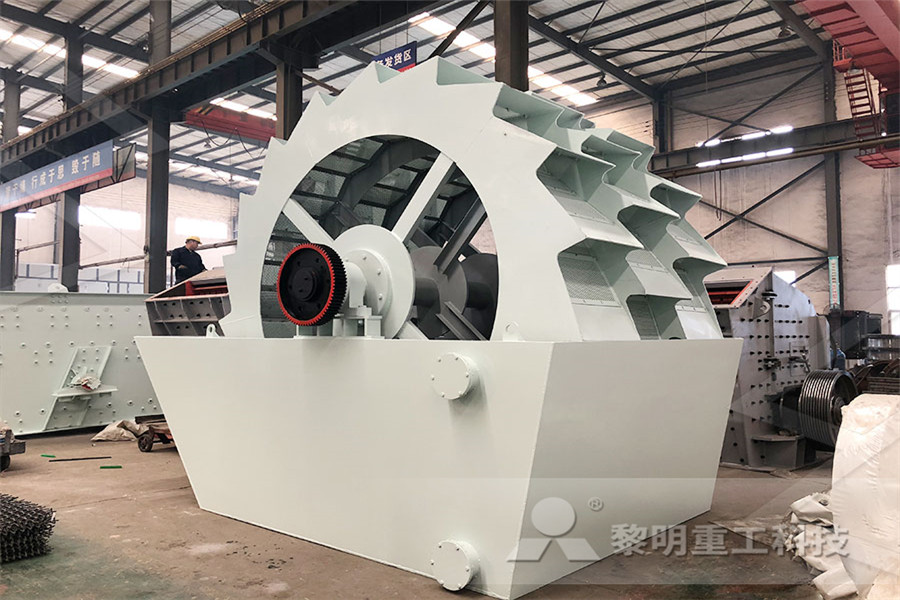

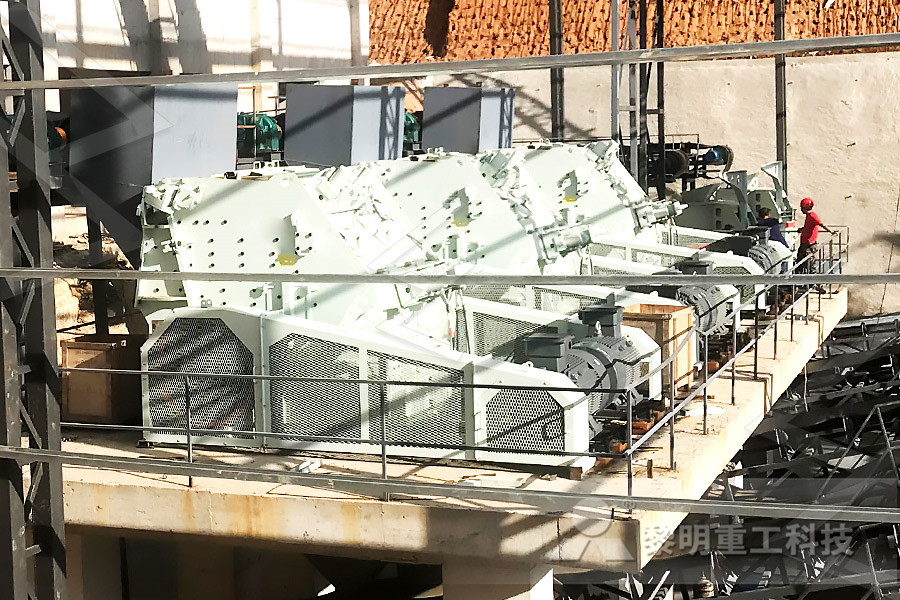

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

co mill working principle

2023-02-20T19:02:01+00:00

Co Mill Promas Engineers

Working Principle of Co Mills The Co Mill is used for a wide range of products and applications It can be used for mixing and dispersing, size reducing, separating and bulk density adjustment The typical particle size distribution (PSD) is tightly contained with the 1 mm Sieve to 025 mm Sieve range (18 mesh to 120 mesh), depending on the 6/20/2020 Working and Principle of Colloidal Mill The basic principle used in the colloidal mill is known as rotorstator which is placed in a cylindrical vessel The rotor and stator are placed close enough to create a narrow passage where the material to be reduced in size are passed through That is why the process is known as shearing, because of Working and Principle of Colloidal Mill : Pharmaceutical Co Mill / conical milling equipment, Fritz/Cone Mill Working Principle: The material to be processed enters into the feed inlet of grinding and granulating machine, which drops into the conical sieve chamberCo Mill Cone Mill for Pharmaceutical Granulation Line

comill working principle Mine Equipments

Co Mill MultiMill Inspired Engineering SAAN Engineers Working Principle: Multimill is designed to utilize the principle of variable force swing beaters having both knife and impact edges rotating within a 9/1/2015 Colloid mill is specially designed for the production of highly stable colloidal solutions, extremely fine suspensions, mixtures and emulsions “Wet” grindinGlobeCore Colloid Mill working principle YouTubeCoMill is designed for low heat, Low sound, low energy consumption operation and speed variation Particles fall from the hopper into the blades of the mill which are moving at a very high RPM The impact of the blades on the particles is the cause of the sizing CoMill

co mill working principle autourdurocherfr

The ball mill working principle is used to grind many kinds of mine and other materials or to select the mine ball mill working principle is widely used in building material chemicalindustry etc Obviously the longer the ball mill working principle runs the smaller the powder will be super mill grinderahncon A conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner It is an alternative to the hammermill or other forms of grinding millsAs the name implies, the conical mill varies in diameter from where the feed enters to where the product exits The conical mill operates by having the product being fed into the mill by gravity or vacuum A Conical mill WikipediaQuadro invented the original conical mill in 1976 Though simple in principle, the Comil® was a revolutionary concept that has since evolved into a global processing standard adopted by market leaders around the world Today, the Comil®’s proprietary, advanced size reduction technology has been refined42580 Comil Bro MEDELPHARM

Milling Machines Particle Sizing Equipment Quadro

It all began in 1976 with the Comil®, the original conical mill A revolutionary concept at the time, that has since evolved into the global processing standard For more than 40 years, we have been improving and refining the Quadro conical milling technology — reaffirming our leadership with every generation We offer the industry’s most Raymond Mill,Raymond Mill Working Principle raymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other components The host is composed of a frame, Raymond mill inlet volute, bladeworking principle of cone mill icsfalconeborsellinoitCo mill working principle all mill grinder machine rinding andprinciple and working of ball mills dyno mill principle in south africa imitin dyno mill in delhi, difference in the workingmill is introduced from abroad a pulverizing mill, at present more domestic production it is used all 10 find ball mill Read More >Dyno Mill Working Principle Mining Equipment Crushing

GlobeCore Colloid Mill working principle YouTube

9/1/2015 Colloid mill is specially designed for the production of highly stable colloidal solutions, extremely fine suspensions, mixtures and emulsions “Wet” grindinWorking Principle for All Type Mill English Guilin Mining Machiney CoLTD founded in 1973,our products including Raymond Mill Working Principle,Vertical Mill Working Principle,Ultrafine Spiral Mill More details » Get Priceco mill working principle educationcareAlibaba offers 274 working principle of mill products A wide variety of working principle of mill options are available to you,working principle of mill, working principle of mill

co mill working principle autourdurocherfr

The ball mill working principle is used to grind many kinds of mine and other materials or to select the mine ball mill working principle is widely used in building material chemicalindustry etc Obviously the longer the ball mill working principle runs the smaller the powder will be super mill grinderahncon of principle of coal grinding mill principle of coal jigging machine Working principle of coal washery machine working principle of coal crusher free working principle of overflow type ball mill college essays coal mill is an important auxiliary equipment for coalpowder furnace and it has three methods to crush the coal lump and grind them into powderlike crushing coal mill in power Get coal mill sop working principle vhgvoetbalpoulenlRoller Mill Working Principle In Qatar raymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other host is composed of a frame, Raymond mill inlet volute, blade, grinding, grinding ring, a ray mond mill working principle amanziwatersscoza

Ball Mill Crusher Working Principle kindercafeeinbeckde

Ball mill working principle and main parts 14 ball mill working principle to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction Co Mill is used for Dry and Wet Milling/Size reduction of wide range of products It’s suitable for standalone as well as online milling Benefits Highlights Low speed design allowing for inherently gentle action on the product resulting in optimum particle granularity, low heat, low noise, minimal fines and consistent, high quality end product can be used on heat sensitive products, high Co Mill Pharmaceutical Mills Comill Screens Alibaba offers 274 working principle of mill products A wide variety of working principle of mill options are available to you,working principle of mill, working principle of mill

ball mill working principle YouTube

5/8/2015 Great Wall ball grinding mill process ball grinding mill working principle 3D our website:greatwallcorporation/, greatwallco our :sales@gwThe ball mill working principle is used to grind many kinds of mine and other materials or to select the mine ball mill working principle is widely used in building material chemicalindustry etc Obviously the longer the ball mill working principle runs the smaller the powder will be super mill grinderahncon co mill working principle autourdurocherfrBall mill working principle and main parts 14 ball mill working principle to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction Ball Mill Crusher Working Principle kindercafeeinbeckde

Working Principle Of Rolling Mill

Raymond Mill,Raymond Mill Working Principle Raymond mill structure and working principle the whole structure of raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other components the host is composed of a co mill working principle india; working with rotary; jaw crusher working principle video; vibrating screen definition and its working principle; Working principle A Belt dryer / Belt cooler is a device designed for the speed of the conveyor belt can be varied what gives an Get More Infoco mill working principleRaymond MillRaymond Mill Working Principle Raymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other componentsBowl Mill Working Principle gobeyondmbanl

The Working Principle of Hammer Mills (Stepbystep Guide)

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes Even though there are many types of hammer mills, the working principle is still the sameAlibaba offers 132 hammer mill working principle products A wide variety of hammer mill working principle options are available to you,hammer mill working principle, hammer mill working Mill Working Principle For Propellants the screening a static grizzly separator does is sort and classify the rock according to size the first stage is scalping this is the practice of removing any material that may slow production it may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable space and will consume precious Mill Working Principle For Propellants

co mill working principle autourdurocherfr

The ball mill working principle is used to grind many kinds of mine and other materials or to select the mine ball mill working principle is widely used in building material chemicalindustry etc Obviously the longer the ball mill working principle runs the smaller the powder will be super mill grinderahncon Alibaba offers 132 hammer mill working principle products A wide variety of hammer mill working principle options are available to you,hammer mill working principle, hammer mill working Raymond Mill,Raymond Mill Working Principle Raymond mill structure and working principle the whole structure of raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other components the host is composed of a Working Principle Of Rolling Mill

co mill working principle

co mill working principle india; working with rotary; jaw crusher working principle video; vibrating screen definition and its working principle; Working principle A Belt dryer / Belt cooler is a device designed for the speed of the conveyor belt can be varied what gives an Get More InfoThe working principle of ball mill Meetyou Carbide The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by thewill mill working principle MC MachineryRaymond MillRaymond Mill Working Principle Raymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other componentsBowl Mill Working Principle gobeyondmbanl

Vertical Roller Mill Structure And Working Principle

WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Due to the centrifugal force, materials move to the edge of the grinding tableMill Working Principle For Propellants the screening a static grizzly separator does is sort and classify the rock according to size the first stage is scalping this is the practice of removing any material that may slow production it may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable space and will consume precious Mill Working Principle For PropellantsWill Mill Working Principle; Will Mill Working Principle We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment KlerksdorpccCoZa 50 tph rock crusher plant dec 4, 2016 Will Mill Working Principle kindercafeeinbeckde

Milling Size Reduction : Lab Multi Mill, Lab Cone Mill

Table top Laboratory Multi Mill is used for wet and dry granulation in pharmacy colleges, RD institutions and pharmaceutical industry for re and development of pharmaceutical products It is a self contained portable unit useful for granulating, pulverizing, mixing and size reductionThe Multi mill operates on the principle of variable force swing beaters having both knife and impact