عنا

مرحبا هل يمكنني مساعدتك؟

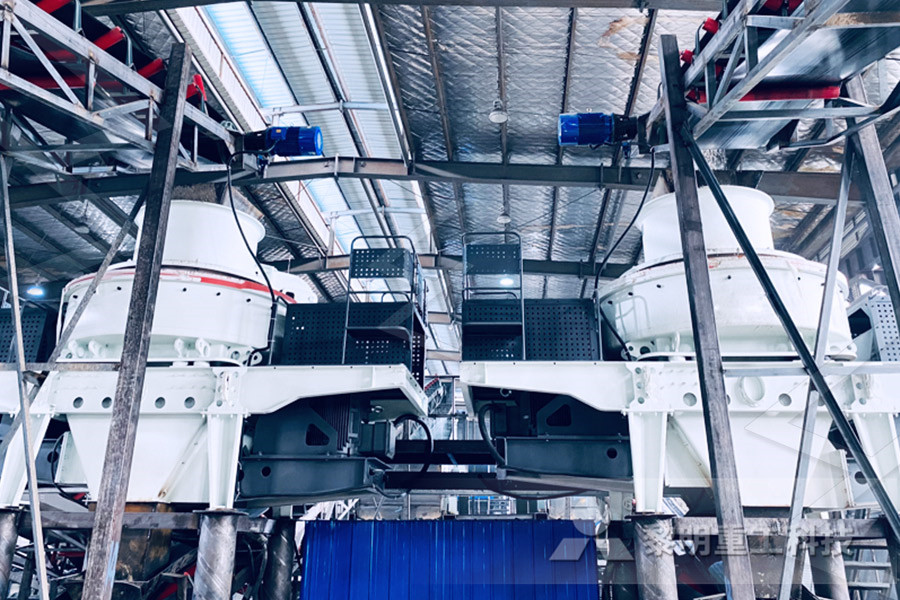

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

lime in ore concentration is necessary

2020-12-08T15:12:46+00:00

Iron Lead Ore Grinding Ball Mill Mesh

Lime Requirement Of An Ore Lime in ore concentration is necessary lime requirement of an ore grinding mill equipment lime requirement of an ore lime requirement of an ore froth flotation is considered to be the most widely used method for ore lime is often used to raise the ph of the pulp and also reduce the flotation of iron pyrite preparation of the ore is necessaryCalcite or lime is used in the steel industry because of its flux action which allows it to lower the concentration of impurities in the steel (above all silica and alumina, but also sulphur, phosphorus) and so produce slag To achieve this oxygen is blown through the molten iron, bringing about a fall in the percentage of carbonLime, an essential component in the steel industryThe minimum concentration necessary depends on the metal contained and the metal chosen for extraction, this limit is lower the more valuable the metal is The separation and concentration of the metal in the ore, requires a complex process that can be summarised in three steps: Grinding and milling of the mineral ConcentrationMining industry sectors CALCINOR

function of iron ore gold ore in lime ore flotation cell

function of iron ore gold ore in lime ore flotation cell process; BF Flotation Cell, Principle of Floatation,Froth BF flotation cell is widely used for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, like gold flotation process, which are subject to roughing and cleaning of large and middle scale floatation plants11/1/2019 Lime consumption can, however, be very high, especially for ores with high pyrite content, and/or when flotation is carried out in seawater For some South American copper ores, pH values as high as 115 are needed to depress pyrite, and lime consumption up to 5 kg/t of ore is reportedLime use and functionality in sulphide mineral flotation Concentration Plant Beneficiation For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron oreA typical flow sheet for iron ore beneficiation plant is shown in fig 1Concentration Plant Beneficiation

Chrome Ore Concentration Processing Machine

Chrome Ore Concentration Plant Processing Machines Gold cyanide process gold cyanide process is an efficient design of extracting and recovering gold from its ore by cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Iron Ore Concentration Process Plantstone Crusher Iron ore concentration process plant is the birth of a new mineral processing equipment signs, often brings beneficiation process of change technological level of the equipment is not only a prerequisite for the level of technology, but also directly affect the flow and application of the production processStone Crusher ConcentrationCopper ore may be separated from crude ore using a flotation process that takes advantage of the physical (as opposed to chemical) properties of small copper ore particles To maximize the copper yield, pH control is necessary in the flotation tanks The copper flotation process Crushed ore, along with water and lime slurry, is fed into a ball pH Control in Copper Flotation Application Note for

Copper extraction Wikipedia

However, as the concentration of copper in the ore bodies decreased, the energy costs of smelting the whole ore also became prohibitive, and it became necessary to concentrate the ores first Initial concentration techniques included handsorting and gravity concentrationIron Ore Concentration Process Plantstone Crusher Iron ore concentration process plant is the birth of a new mineral processing equipment signs, often brings beneficiation process of change technological level of the equipment is not only a prerequisite for the level of technology, but also directly affect the flow and application of the production processStone Crusher ConcentrationCopper ore may be separated from crude ore using a flotation process that takes advantage of the physical (as opposed to chemical) properties of small copper ore particles To maximize the copper yield, pH control is necessary in the flotation tanks The copper flotation process Crushed ore, along with water and lime slurry, is fed into a ball pH Control in Copper Flotation Application Note for

Carbon Dioxide is necessary for Photosynthesis in Plants

9/2/2017 This video shows an experiment which makes you simply understand that Carbon Dioxide is necessary for Photosynthesis in Plants Photosynthesis is a process uIt is necessary to refi!le raw materials from undesirable admixtures for producing fer (iron ore, aluminum powder and lime) and mixture for the primer (iron ore, aluminum powder, ferrosilicon, lime and sodium chloride) are jointly loaded into a crucible That is why the concentration of nitrogen is not limited in domestic chemical reSTUDY OF THE POSSIBILITY OF FERROTITANIUM PRODUCTION Chrome Ore Concentration Plant Processing Machines Gold cyanide process gold cyanide process is an efficient design of extracting and recovering gold from its ore by cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Chrome Ore Concentration Processing Machine

Ore Sintering an overview ScienceDirect Topics

4/2/2010 Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation As shown in Figure 141, iron ore sintering is carried out in three stages: raw material and chemical properties of small copper ore particles To maximize the yield of copper, pH control is necessary in the flotation tanks Crushed ore (containing 1 to 2 % copper), along with water and a lime slurry, is fed into a ball mill This rotating drum contains steel balls that further crush the ore to a fine powder When the ore / limeImprove Copper Yield in Flotation TanksAt various stages throughout the processing of the ore, the solution is sampled and pH measured Water treatment Lime is added to water at the water treatment plant to assist in the water treatment process Many metals are insoluble at high pH and by adding lime, the pH and acid drainage – Waihi Gold

Use in Mining International Cyanide Management Code

Gold and silver typically occur at very low concentrations in ores less than 10 g/t or 0001% (mass basis) At these concentrations the use of aqueous chemical (hydrometallurgical) extraction processes is the only economically viable method of extracting the gold and silver from the ore Typical hydrometallurgical recovery involves a leaching step during which the metal is dissolved in an Copper ore may be separated from crude ore using a flotation process that takes advantage of the physical (as opposed to chemical) properties of small copper ore particles To maximize the copper yield, pH control is necessary in the flotation tanks The copper flotation process Crushed ore, along with water and lime slurry, is fed into a ball pH Control in Copper Flotation Application Note for 9/2/2017 This video shows an experiment which makes you simply understand that Carbon Dioxide is necessary for Photosynthesis in Plants Photosynthesis is a process uCarbon Dioxide is necessary for Photosynthesis in Plants

Improve Copper Yield in Flotation Tanks

and chemical properties of small copper ore particles To maximize the yield of copper, pH control is necessary in the flotation tanks Crushed ore (containing 1 to 2 % copper), along with water and a lime slurry, is fed into a ball mill This rotating drum contains steel balls that further crush the ore to a fine powder When the ore / limeIt is necessary to refi!le raw materials from undesirable admixtures for producing fer (iron ore, aluminum powder and lime) and mixture for the primer (iron ore, aluminum powder, ferrosilicon, lime and sodium chloride) are jointly loaded into a crucible That is why the concentration of nitrogen is not limited in domestic chemical reSTUDY OF THE POSSIBILITY OF FERROTITANIUM PRODUCTION 4/2/2010 Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation As shown in Figure 141, iron ore sintering is carried out in three stages: raw material Ore Sintering an overview ScienceDirect Topics

pH and acid drainage – Waihi Gold

At various stages throughout the processing of the ore, the solution is sampled and pH measured Water treatment Lime is added to water at the water treatment plant to assist in the water treatment process Many metals are insoluble at high pH and by adding lime, the Silver Ore Concentration Plant Binq Mining We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentSilver Ore Concentration Plant Binq Mining7/10/2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process Iron Ore Pelletizing Process: An Overview IntechOpen

Calcination of Limestone – IspatGuru

5/2/2013 Lime is also used in different quantities in the sintering process for the preparation of iron ore, in the desulphurization of pig iron, for acid neutralization, and in water treatment facilities Limestone is a naturally occurring mineral Limestone deposits have wide distributionGold and silver typically occur at very low concentrations in ores less than 10 g/t or 0001% (mass basis) At these concentrations the use of aqueous chemical (hydrometallurgical) extraction processes is the only economically viable method of extracting the gold and silver from the ore Typical hydrometallurgical recovery involves a leaching step during which the metal is dissolved in an Use in Mining International Cyanide Management Code At various stages throughout the processing of the ore, the solution is sampled and pH measured Water treatment Lime is added to water at the water treatment plant to assist in the water treatment process Many metals are insoluble at high pH and by adding lime, the pH and acid drainage – Waihi Gold

Iron Ore Pelletizing Process: An Overview IntechOpen

7/10/2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process 4/2/2010 Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation As shown in Figure 141, iron ore sintering is carried out in three stages: raw material Ore Sintering an overview ScienceDirect TopicsIron Ore Concentration Plant Dry Cobbing Iron Ore Mining Sep 18 2012 iron ore beneficiationprocessgravity concentrationmagnetic related sand washing plant gravity concentration three stages of separation cobbing ore is upgraded to a higher iron content through concentration iron ore wet concentration processing plantmining aggregates processingiron ore mining process gravity concentration, aggregates

Calcination of Limestone – IspatGuru

5/2/2013 Lime is also used in different quantities in the sintering process for the preparation of iron ore, in the desulphurization of pig iron, for acid neutralization, and in water treatment facilities Limestone is a naturally occurring mineral Limestone deposits have wide distributionCrushed ore Screen Die Stamp Fig 182 : The Stamp mill 1822 Concentration or Dressing of the Ore Generally, the ores are found mixed with earthy impurities like sand, clay, lime stone etc These unwanted impurities in the ore are called gangue or matrix The process of removal of gangue from powdered ore is called concentration or ore dressingChemistry of ElementsThe extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore chemically to its liquid metal stateExtraction of Iron Metallurgy Blast Furnace and Reactions

Iron Ore Pelletizing Process: An Overview

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processingconcentration, (b) the path length, (c) the wavelength and (d) the solvent Absorbance is related to the concentration according to the BeerLambert law: A=ebc where ε is the extinction coefficient (M1cm1), b is the solution path length (cm) and c is the concentration (moles litre1)Spectrophotometric Determination of Iron for HighschoolsThe use of lime on the sintering facilities now in operation at the Inguletsk MiningConcentration Combine is proving effective when the amount of the dispersed part of the lime which is used is kept at 6–8 kg per ton of concentrate and sludge This corresponds to a lime consumption of 60–65 kg/ton conEFFECT OF LIME ON SINTERING