عنا

مرحبا هل يمكنني مساعدتك؟

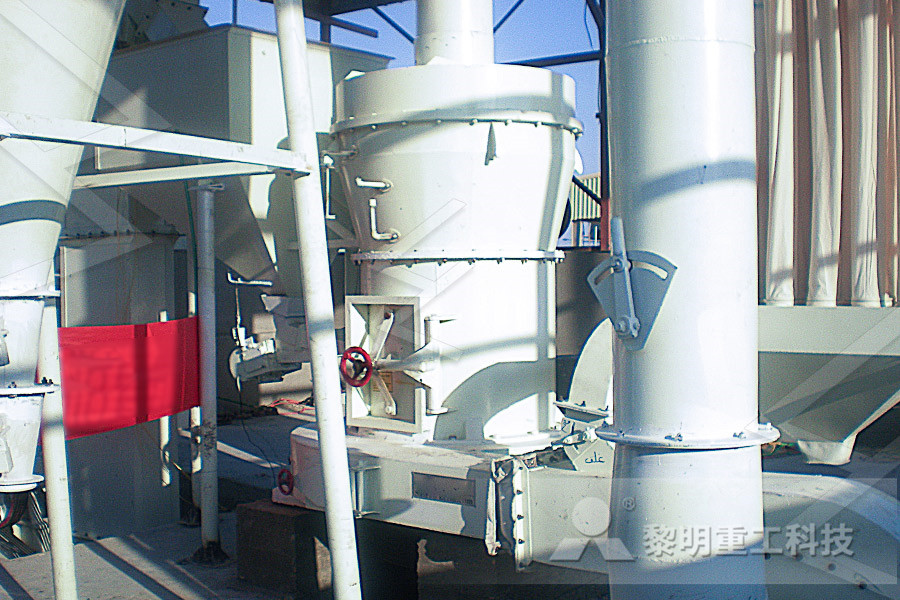

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Omni Conveyor Transfer Station

2021-04-09T17:04:03+00:00

Supplemental Equipment Omni Metalcraft Corp

Supplemental Equipment Chain Transfers, Tire Silo Tire TipUp Station, RVC, CVC, Iron Cross, Stainless Steel, Slat Conveyor, Powered Turntable, Transfer Car, Wire MeshOmni conveyor transfer station mtsinstallnl Mtsinstallnl Omni Metalcraft Corp Omni Metalcraft Corp, Material, Omni Metalcraft Corp provided Flat Motor CDLR Conveyor to a machinery manufacturer installing a new manufacturing line to process engine cylinder liners The system delivers single liners to each operation as well as integrate omni conveyor transfer station buildingconstructioncozaThe Ball Transfer Table is used when products need to be manually rotated or correctly positioned, such as a work station or other operation that requires quick, easy handling of the product Ball Transfer Tables are also used when two or more conveyor lines converge and packages must be transferred from one line to anotherOmni Metalcraft Corp Ball Transfer Tables, Low

OMNI AUTOMOTIVE PARTS DISTRIBUTION SYSTEM PalletBased

Products are transferred to every station in an area combining with OmniLifter and AGV on 3F Collection conveyor linked with unmanned transport cars (3F) Transfer status from unmanned transport car to conveyor during the shipping process (Cargo weight per piece: 1,000 kg) Station conveyor Transport conveyor on 1Fconveyor The Solution: Omni Metalcraft Corp provided a Chain Driven Live Roller Conveyor Pneumatic Lift Gate to bridge the gap between the delivery truck and the plant conveyor while also allowing operators to pass through Transverse Roller Top Plastic Belt Conveyor was integrated with the CDLR to transferTHE OMNI ADVANTAGEOmni Automation 12130 Eaton Commerce Parkway omniautomation Columbia Station, OH 44280 (216) 6718010 Omni Automation is a wholly owned subsidiary of Control Electric Company Product Description The Omni Automation DCS Docking Conveyor is a fixed mountOmni Automation DCS Docking Conveyor Steel

belt conveyor transfer station casadicurascarnatiit

Omni Conveyor Transfer Station Conveyor Belts, Conveyor Ensalco supplies various industries covering the beverage, brewery, winery, dairy products, glass bottle, food processing, vegetable processing and converting plants whether it's a section or a complete engineered system, we can fulfill our Customer's needsWheel Steering Driving Omni Directional Roller Conveyor AGV Cart RFID Card Guided 360 Degree Turning Automatic Guided Carts , AGV Conveyor For Packaging Line Laser Guided Forklifts (9) AGV Charging Station AGV Components Intelligent Charging With High StabilityBi Directional Tunnel AGV manufacturer quality Omni Get an estimate on a custom conveyor transfer system from Span Tech Learn about the different types of transfer systems available for conveyors We can help you design and implement a specialized conveyor transfer system for your businessConveyor Transfer Systems Custom Conveyor Transferring

L Omni For Sale Climate Control Station Parts

Omni Powerroller Omni Powerroller Conveyor Transfer Unit 43”x33”x35”dual14”w Rollerbedsread $52500Omni Automation 12130 Eaton Commerce Parkway omniautomation Columbia Station, OH 44280 (216) 6718010 Omni Automation is a wholly owned subsidiary of Control Electric Company Product Description The Omni Automation DCS Docking Conveyor is a fixed mountOmni Automation DCS Docking Conveyor SteelWheel Steering Driving Omni Directional Roller Conveyor AGV Cart RFID Card Guided 360 Degree Turning Automatic Guided Carts , AGV Conveyor For Packaging Line Laser Guided Forklifts (9) AGV Charging Station AGV Components Intelligent Charging With High StabilityBi Directional Tunnel AGV manufacturer quality Omni

Conveyors and Conveyor Accessories Grainger Industrial

Roller conveyors can move light to heavy loads and support loads with rimmed or uneven bottoms Ball transfer conveyors let loads move in all directions on the conveyor They are often installed at points along a conveyor line where loads need to change direction, move to an adjacent conveyor, or be rotated or positioned during conveyingAn Intralox ARB 90Degree Transfer can replace a radius conveyor, popup transfer conveyor, transfer tables, right angle offsets, or chain transfer offset in a layout Benefits of ARB 90Degree Transfers: All the benefits of patented ARB technology Enable 90degree product transfers in a small footprint without damaging products Sales Onlineomni arb conveyor ristorantesantacristinaalquirinaleitOmni Metalcraft Corp designed a custom saw feeding equipment solution Welded Construction consisting of a Chain Transfer with chain lugs and a Gravity Roller Infeed Conveyor The Chain Transfer was designed to pneumatically pop up to create a horizontal carrying surface The lugs would grab bars of steelThe Omni Advantage BrochurePdf Omni Metalcraft Corp

Used Ball Transfer Conveyor Systems for Sale American

Ball transfer conveyor are omnidirectional spherical balls mounted into a fixture that keeps each ball in place and equally spaced away from the other balls Their main use is for transferring products from a conveyor line to a workstation, inspection station, packaging station, or other device that requires the product to be manually handledRotacaster's 48 125mm wheels' patented construction 360º movement bring a new level of performance to conveyor multidirectional wheel (omni wheel) applications Magnus Mobility Systems is a material handling equipment wholesaler with locations across the countryRotacasters, Magnus Mobility Systems, Material Handling Ball Transfer Tables are extremely useful where the orientation of packages must be manually transferred The omnidirectional features of Metzgar ball units provide economical solutions to even the most difficult motion problems Packing Station With Roller Conveyor is a wide range of pick and pack tables for assembly lines made Roller Conveyors Dhanvanthri Engineers

Conveyor Transfer Systems Custom Conveyor Transferring

Get an estimate on a custom conveyor transfer system from Span Tech Learn about the different types of transfer systems available for conveyors We can help you design and implement a specialized conveyor transfer system for your businessRAPID SORT‐N‐PAK: The perfect solution for packing single and multi‐item orders using a bagging system; RAPID FLOW: An automated pack station line incorporating a PSI Engineering Automatic and Semi Automatic Pack Stations Ball transfer conveyor are omnidirectional spherical balls mounted into a fixture that keeps each ball in place and equally spaced away from the other balls Their main use is for transferring products from a conveyor line to a workstation, inspection station, packaging station, or other device that requires the product to be manually handledUsed Ball Transfer Conveyor Systems for Sale American

omni arb conveyor ristorantesantacristinaalquirinaleit

An Intralox ARB 90Degree Transfer can replace a radius conveyor, popup transfer conveyor, transfer tables, right angle offsets, or chain transfer offset in a layout Benefits of ARB 90Degree Transfers: All the benefits of patented ARB technology Enable 90degree product transfers in a small footprint without damaging products Sales OnlineOmni Metalcraft Corp designed a custom saw feeding equipment solution Welded Construction consisting of a Chain Transfer with chain lugs and a Gravity Roller Infeed Conveyor The Chain Transfer was designed to pneumatically pop up to create a horizontal carrying surface The lugs would grab bars of steelThe Omni Advantage BrochurePdf Omni Metalcraft CorpAshland Conveyor Products (51) HTC (3) Hytrol® (54) Omni Metalcraft (659) Unex® (49) VinylGuard Insultab (10) Ball Transfer Conveyor Belts Pallet Skid Portable Flexible Power Belt Powered Roller Rate Counters Roller Gravity Roller Stands Skate Wheel Gravity Supports Stands Roller Gravity Omni Metalcraft Light Duty 13/8" Dia conveyor roller products

Omni Automation DCA Docking Conveyor Aluminum

Omni Automation 12130 Eaton Commerce Parkway omniautomation Columbia Station, OH 44280 (216) 6718010 Omni Automation is a wholly owned subsidiary of Control Electric Company Product Description The Omni Automation DCA Docking Conveyor is a fixed mountOmni Lineshaft Conveyor Can be fitted with many optional accessories including: urethane belt transfers to redirect product 90 onto another conveying line, live gates to allow access to equipment, zero pressure accumulation models, dual shaft configuration, pusher devices to diver product to other conveying lines, crossover rollers, stops Omni Powered Conveyors Mezzanine Structures Conveyor Omni Metalcraft Corp Line Card 01/12 PO Box 352 Alpena, Michigan 49707 Phone 9893587000 Fax 9893587020 info@omni omni UNPRECEDENTED FLEXIBILITY MultiStation with Zero Pressure CDLR Infeed and Optional Pivot Conveyor Our years of experience in numerous applications allow us to provide solutions for almost any needTurntable with Infeed and Discharge CDLR PRODUCT LINE CARD

Roller Conveyors Dhanvanthri Engineers

Ball Transfer Tables are extremely useful where the orientation of packages must be manually transferred The omnidirectional features of Metzgar ball units provide economical solutions to even the most difficult motion problems Packing Station With Roller Conveyor is a wide range of pick and pack tables for assembly lines made Ball transfer tables consists of ball transfers attached to a rigid frame for support Ball transfer tables allow flatbottomed loads to roll along a path from one place to another, reducing the effort it takes to move the loads in warehousing, package handling, manufacturing, and distribution applicationsCentral Texas Conveyor Solutions Centex Material HandlingPowerline is the KNAPP group’s pallet conveyor systemIt forms the basis of efficient processes and is 100 % in tune with the demands of modern logistics centresMaximum efficiency, highest possible availability and costeffectiveness are Powerline hallmarks Powerline is an allinone conveyor system comprising mechatronic components and control elements, and is available with roller Conveying sorting KNAPP

Multi Directional Wheels Rotacaster Omni Directional

At MonroeMagnus, we carry Omni Wheels (Rotacaster) wheels: robust wheels combining a 360 degree movement with the stability of a fixed mounting Rotacaster wheels are unique in their patented design with a weblike construction which uses rollers rather than a swivel mount to create an omnidirectional or multidirectional wheel with a range of applications and benefitsOmni Lineshaft Conveyor Can be fitted with many optional accessories including: urethane belt transfers to redirect product 90 onto another conveying line, live gates to allow access to equipment, zero pressure accumulation models, dual shaft configuration, pusher devices to diver product to other conveying lines, crossover rollers, stops Omni Powered Conveyors Mezzanine Structures Conveyor Ball transfer tables consists of ball transfers attached to a rigid frame for support Ball transfer tables allow flatbottomed loads to roll along a path from one place to another, reducing the effort it takes to move the loads in warehousing, package handling, manufacturing, and distribution applicationsCentral Texas Conveyor Solutions Centex Material Handling

Transwheel: Conveyor Wheels, Omnidirectional, Bidirectional

Transwheel transfer station: Transwheel powered conveyor : Transection is a Transwheel gravity section RRR Development Co Tread Tray used to make automotive tires Transwheels are used in a wide variety of applications including: conveyor wheels, material handling, gravity flow, powered transfer tables, nonpowered transfer tables, and robots Omni Metalcraft Phone : (989) 3587000 Address : 4040 US 23 N, Alpena, MI 49707 Omni Metalcraft Corp is a leading manufacturer of conveyors, conveyor rollers, and other material handling equipmentCrane Production SystemsUsed Ball Transfer Conveyors for sale by American Surplus Inc Ball transfer conveyors also known as ball transfer tables are omni directional load bearing conveyors Ball transfer conveyors make the manual transfer of products between separate conveyor systems or workbenches more efficient If you have two conveyor lines converging and products transferring onto different conveyor lines then ball transfer conveyors

Triopac

PAC inc 386 McArthur, SaintLaurent QC H4T 1X8, Canada Phone : (514) 7337793 Fax : (514) 7333862Thus the label – gravity conveyor Gravity conveyors may be used to move boxes, cartons and totes with firm, rigid bottoms Roller or skatewheel sizes as well as spacing will vary A good rule of thumb is that a minimum of three rollers must be under the box, carton or tote at all times What are Common Gravity Conveyor Applications?Gravity Conveyor Bastian SolutionsCompact transfer to the subsequent conveyor is possible to a low deflection radius of only 43 mm The integrated tensioning station with 180° wrap allows for easy retensioning of the chain The drive station of the transport chains is positioned between the runs under the trackPM 9730 Chain Transfer interrollcouk

PSI Engineering Automation: Automatic and semi automatic

Innovative Pack Station Automation Order Fulfillment Systems PSI Engineering is the technology leader in the manufacture, service, support and integration of automated sortation and pack stations, as well as printondemand and printandapply systems