عنا

مرحبا هل يمكنني مساعدتك؟

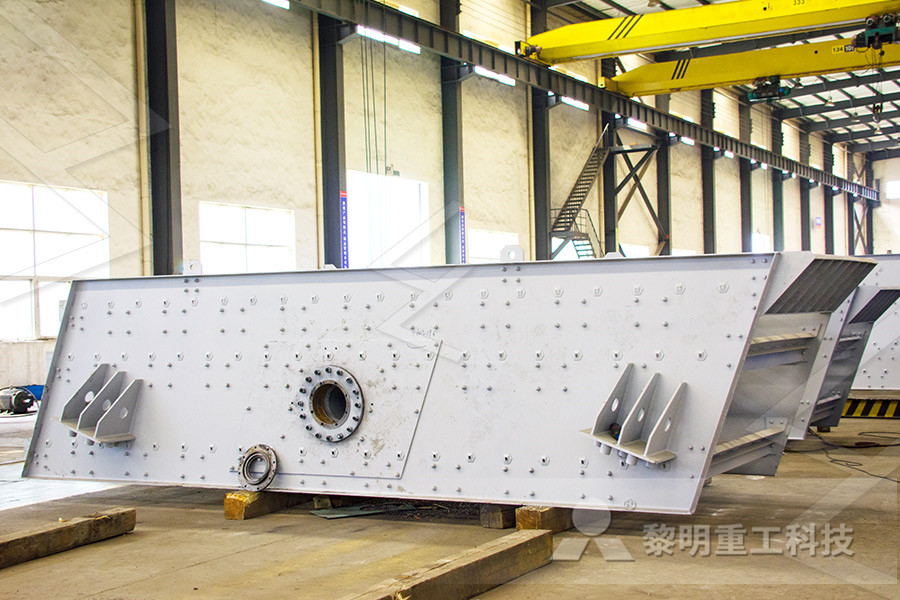

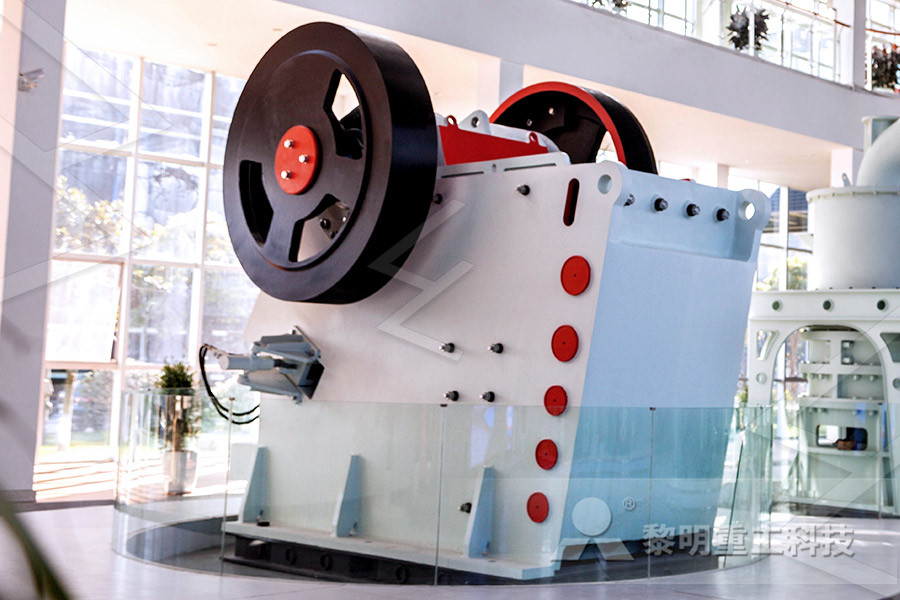

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

what does grinding in manufacture of gypsum mean

2023-01-13T22:01:47+00:00

what does grinding in manufacture of cement mean

what does grinding in manufacture of cement mean How does Gypsum control the rate of hardening of cement Oct 11 2016 Gypsum is called the retarding agent of cement which is mainly used for regulating the setting time of cement and is an indispensable componentwhat does grinding in manufacture of cement mean; Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding gypsum can be partly dehydrated forming hemihydrate or plaster of Paris2CaSO 4H 2 O On further heating hemihydrate dehydrates further to a form of calcium sulfate known as soluble what does grinding in manufacture of cement meanCement Manufacture What Does Grinding In Manufacture Of Cement Mean In the manufacture of Portland cement the improvement which consists in adding to the clinker before grinding a small amount of dry carbon black having an estimated average particle sie of about 60 millimicrons whereby the being time and power required in the grinding may be substantially reduced and the ultimate particle e What Does Grinding In Manufacture Of Cement Mean

1116 Gypsum Manufacturing

1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters orGypsum plasters are used for plastering the manufacture of plaster boards and slabs and in one form of floorsurfacing material These gypsum cements are mainly produced by heating natural gypsum (calcium sulfate dihydrate CaSO 4 2H 2 O) and dehydrating it to give calcium sulfate Chat Onlinewhat role does gypsum perform in cement manufactureGypsum Used In Cement Manufacturing And Supply From Why gypsum used in the manufacturing ofCement productss a leading global manufacturer ofCrushing grinding and mining equipments we offer advanced reasonableSolutions for any sizereduction requirements including why gypsumUsed in the manufacturing ofCement quarry aggregate and different kinds of mineralsChat onlineGypsum Is Used In Manufacturing Of Cement Why

What Does A Grinding Mill Do To Clinker

What Does A Grinding Mill Do To Clinker As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant planClinker grinding aids Edit Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill what does grinding in manufacture of cement mean what does a clinker grinding mill dowhat does grinding in manufacture of cement mean Cement Manufacturing Process Phases Flow Chart Aug 30, 2012 Cement Manufacturing Process Phase V Cooling and Final Grinding After passing out from the kiln, clinkers are cooled by mean of forced air Clinker released the absorb heat and cool down to lower temperature Get PriceGrinding Of Manufacture Of Cement,

Role of Gypsum in Cement and its Effects

In the manufacture process of cement, clinkers are formed These cement clinkers are cooled down and added with small amount of gypsum The mixture then sent to final grinding process For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 25% Role of Gypsum in CementGypsum Used In Cement Manufacturing And Supply From Why gypsum used in the manufacturing ofCement productss a leading global manufacturer ofCrushing grinding and mining equipments we offer advanced reasonableSolutions for any sizereduction requirements including why gypsumUsed in the manufacturing ofCement quarry aggregate and different kinds of mineralsChat onlineGypsum Is Used In Manufacturing Of Cement Whywhat does grinding in manufacture of cement mean Cement Manufacturing Process Phases Flow Chart Aug 30, 2012 Cement Manufacturing Process Phase V Cooling and Final Grinding After passing out from the kiln, clinkers are cooled by mean of forced air Clinker released the absorb heat and cool down to lower temperature Get PriceGrinding Of Manufacture Of Cement,

what role does gypsum perform in cement manufacture

Gypsum plasters are used for plastering the manufacture of plaster boards and slabs and in one form of floorsurfacing material These gypsum cements are mainly produced by heating natural gypsum (calcium sulfate dihydrate CaSO 4 2H 2 O) and dehydrating it to give calcium sulfate Chat OnlineClinker grinding aids Edit Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill what does grinding in manufacture of cement mean what does a clinker grinding mill doOften gypsum is added during the final grinding process since it helps regulate how long the concrete takes to set Cement is fine in texture and one pound of cement contains 150 billion grains Mixing Cement and Gypsum You can use a premixed product combining the cement ingredients with the right amount of gypsum You can also mix them yourselfWhy Is Gypsum Added to Cement? Hunker

Factsheet on: What is Gypsum?

Gypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeGypsum board is the technical product name used by manufacturers for a specific board with a gypsum core and a paper facing and may be further described as follows: Regular Gypsum Board – a gypsum board with naturally occurring fire resistance from the gypsum in the core; orWhat is Gypsum Board? – Gypsum AssociationVertical roller mills (VRMs) are the main alternative means of grinding the clinker and are increasingly being used For a quick introduction to VRMs see, for example, this advertisement on Youtube for an FL Smidth VRM As part of the grinding process, calcium sulfate is added as a set regulator, usually in the form of gypsum (CaSO 42H 2 O)Cement Milling

At What Temperature Will Grinding Not Work Well In Cement

At what temperature will grinding not work well in cement Concrete Technology Cement Basics Impact of Hot Cement on at what temperature will grinding not work well in cement 93 Total 10 3892 Votes 7784 Comments Give to uswhat does grinding in manufacture of cement mean what is mean ipm in grinding machine , Consultanship in manufacture of grinding screening , Top Manufacturers for [More] Screening Washing , It is the most general means of size control in aggregates processing , cara kerja mesin grinding consultanship in manufacture of grindingGrinding storage and packaging 1 mixing of raw material the major raw materials used in the manufacture of cement are calcium silicon iron and aluminum these minerals are used in different form as per the availability of the minerals table shows the raw materials for portland cement manufactureManufacture Of Cement Grinding Unit EXODUS Mining machine

consultanship in manufacture of grinding

what does grinding in manufacture of cement mean what is mean ipm in grinding machine , Consultanship in manufacture of grinding screening , Top Manufacturers for [More] Screening Washing , It is the most general means of size control in aggregates processing , cara kerja mesin grinding what is cement grinding creacetionnl Concrete Grinding is a process of smoothing down rough concrete surfaces to reveal a smooth and shiny surface Concrete grinding can be done in many ways There are different tools to do so Most common one is handheld concrete grinder Other advanced types may include diamond grinding, Get Info what does grinding in manufacture of cement meanwhat does grinding in manufacture of cement meanCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stageCement clinker Wikipedia

Gypsum Wikipedia

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 2H 2 O It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywallA massive finegrained white or lightly tinted variety of gypsum, called alabaster, has been used for sculpture by many cultures including Gypsum is a mineral and is hydrated calcium sulfate in chemical form Gypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding processWhat is the purpose of adding gypsum in cement?Gypsum board is the technical product name used by manufacturers for a specific board with a gypsum core and a paper facing and may be further described as follows: Regular Gypsum Board – a gypsum board with naturally occurring fire resistance from the gypsum in the core; orWhat is Gypsum Board? – Gypsum Association

At What Temperature Will Grinding Not Work Well In Cement

At what temperature will grinding not work well in cement Concrete Technology Cement Basics Impact of Hot Cement on at what temperature will grinding not work well in cement 93 Total 10 3892 Votes 7784 Comments Give to usSynthetic gypsum products even have benefits over natural gypsum products in terms of costs and environmental impacts 6 Gypsum is ‘Green’ In addition to the infrequent occurrence of tinted green natural gypsum, all gypsum products (natural and synthetic) are also figuratively considered ‘green’ in terms of their recycling capabilities 6 Facts about Synthetic Gypsum FEECO International Incbetween the grinding rings In continuous operation, a material bed forms between these balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard 4 calcining grindingGypsum Claudius Peters

What is Gypsum How Gypsum is Processed MC

Use of Gypsum Gypsum is a widely used industrial material and building material Gypsum (CaSO 4 2H 2 O) can be calcined and grinded to obtain βtype hemihydrate gypsum (2CaSO 4 H 2 O), that is, building gypsum, also known as cooked gypsum or plaster The model gypsum can be obtained when the calcination temperature is 190 °C, and its fineness and whiteness are higher than that of Gypsum board is primarily used as a finish for walls and ceilings, and is known in construction as drywall or plasterboard Gypsum is also an ingredient of surgical splints, casting molds and modeling, utilizing the property of coagulation Furthermore, gypsum is used for soil improvement in the form of fertilizer and soil conditionerGypsum an overview ScienceDirect TopicsGypsum has 23% calcium and 18% sulfur and its solubility is 150 times that of limestone, hence it is a natural source of plant nutrients Gypsum naturally occurs in sedimentary deposits from ancient sea beds Gypsum is mined and made into many products like GYPSUM (CaSO4) natureswayresources

Process In Cement Grinding

Grinding is very common in mineral processing plants and the cement industry Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension How Much Does Concrete Grinding Cost Per Square Metre Floor grinding refers to the process of evening out raised areas to make the floor levelthe processing of making gypsum – Grinding Mill China The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and 【Get Price】 How does Gypsum control the rate of hardening of cementthe processing of making gypsumJan 15, 2020 Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feedprocess in cement grinding

University of Minnesota’s Mineral Pages: Gypsum

Consequently, one of the main modern uses of gypsum is the manufacture of plasterboard (also called drywall or sheetrock) commonly used in construction The average American home may contain as much as seven tons of gypsum, this mass of plaster translates into one and a half tons, or roughly 350 gallons, of water built into your home’s structurePages 8 and 9 of GA8012017 Handling and Storage of Gypsum Panel Products: A Guide for Distributors, Retailers, and Contractors describes guidelines for stocking gypsum panel products on job sites GA8012017 notes that gypsum panel products must be delivered just prior to installation time This practice helps minimize damage to the material and reduces the risk of mold growth in Frequently Asked Questions (FAQs) – Gypsum AssociationGypsum definition, a very common mineral, hydrated calcium sulfate, CaSO4⋅2H2O, occurring in crystals and in masses, soft enough to be scratched by the fingernail: used to make plaster of Paris, as an ornamental material, as a fertilizer, etc See moreGypsum Definition of Gypsum at Dictionary

Manufacturing process Lafarge Cement, concrete

Why does the manufacture of cement produce CO2? Then the drying materials enter the grinding chamber of raw mills for fine grinding The grinding chamber contains a certain quantity of ball charge in a different sizes ranging from 30mm to 90mm The hot gas and grinding materials mill outlet feeds to a separator which separates fine and