عنا

مرحبا هل يمكنني مساعدتك؟

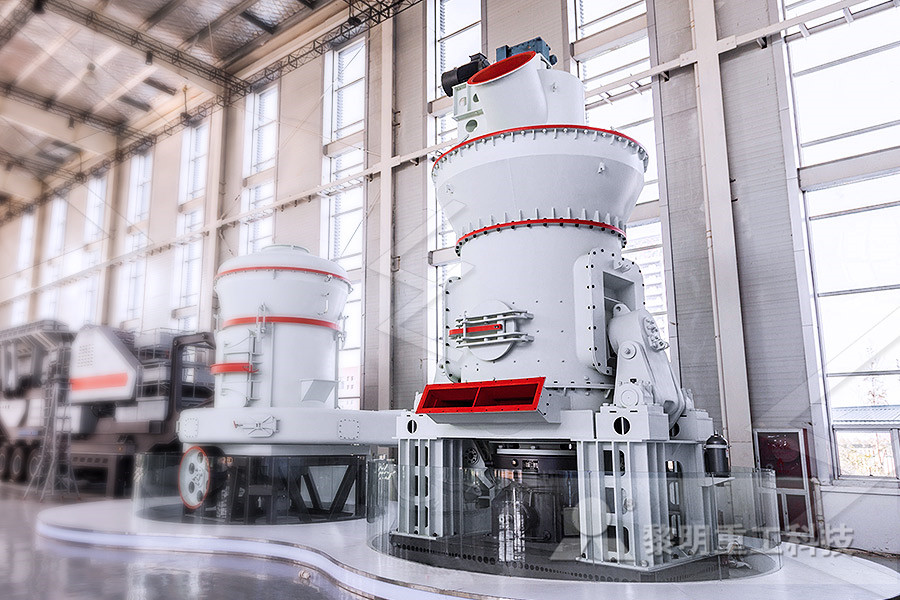

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

effect of ball mill grinding process

2023-06-28T16:06:56+00:00

Effect Of Ball Grinding Mill Process

Ball Size Effect On Grinding Mill The 2080 mill is capable of feed rates equal to a 60 hp standard ball mill, but grinds faster and finer than the ball mill is capable of grinding the vke mill produces up to 10 gs of force, compared to the ball mills 1 g all vke mills are capable of wet or dry grinding and continuous classified productionEffect Of Ball Mill Grinding Process Effect Of Ball Mill Grinding Process We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentgrinding process in ball mill1/1/2011 The objective of this study is to investigate the effects of process variables, such as grinding time, stirrer speed, slurry concentration and ball filling ratio on mill grinding performance For this, batch wet grinding tests were performed in a laboratory stirred ball mill using statistical design 2 Experimental 21 MaterialsA study on the effect of process parameters in stirred

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightEffect Of Media Sie In Ball Mill Dry Grinding Mining We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentEffect Of Media Sie In Ball Mill Dry Grinding MiningEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries It is costly and an inefficient process in milling, its contribution and effect on milling kinetics, load behaviour and mill powerEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

26 Effect of ball mixture 37 261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46effect of ball top size ball mill; effect of cement mill temperature on cement properties; effect on compressive strength of concrete made with crusher dust and gravel effect of silica in cement vertical raw mill grinding; effect of total moisture on coal during pulverising in bowl mill; effect of stone crusher on human societycascading effect in ball millThe following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different Factors Affecting Ball Mill Grinding Efficiency

cascading effect in ball mill

effect of ball top size ball mill; effect of cement mill temperature on cement properties; effect on compressive strength of concrete made with crusher dust and gravel effect of silica in cement vertical raw mill grinding; effect of total moisture on coal during pulverising in bowl mill; effect of stone crusher on human societyEffect Of Media Sie In Ball Mill Dry Grinding Mining We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentEffect Of Media Sie In Ball Mill Dry Grinding MiningEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries It is costly and an inefficient process in milling, its contribution and effect on milling kinetics, load behaviour and mill powerEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Optimization of mill performance by using

mill performance could become worse or better by putting in a new shell liner Data from pilot plant test work illustrates the influence of the shell lifting effect on the grind for a primary grinding duty Figure 5 shows the evolution of the mill discharge product size in relation to the lifting effect of the linersBall mills are equipments which has balls as grinding media and used for last step of grinding process There are many factors which effect grinding performance of ball mills like; liner design (PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES 6/1/2018 During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig 1A chemical reaction on the other hand can consist of say reactant ‘A’ forming intermediate product ‘B’ then proceeding to final product ‘C’ or a competing reactant ‘A’ to final product ‘D’ can also Effect of ball and feed particle size distribution on the

EFFECTS OF FLUIDS ON VIBRATION BALL MILL GRINDING

vibration ball mill with viscous fluids It was also found that surface tension and dipole moment of grinding fluids affect the fracture energy of materials, and that viscosity affects the impact velocity (energy) of the ball26 Effect of ball mixture 37 261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERSAn industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classification performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit Mass balance of the circuit was done by JKSimMet Steady State Effect of ball load and size distribution on grinding and

Factors That Affect the Grinding Effect of Overflow Type

Factors That Affect the Grinding Effect of Overflow Type Ball Mill 6:45:18 XinHai Views (2800) Warm Tip: If you want to know more information, like quotation, products, solutions, etc, please Click here , and contact us onlineProcess Of Roller Press Grinding Ball Mill Roller Press Ball Mill Cement Mill Caesar Heavy Machinery Cement Mill Roller Press Working Principle Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding Over the last three process of roller press grinding ball millBall mills are equipments which has balls as grinding media and used for last step of grinding process There are many factors which effect grinding performance of ball mills like; liner design (PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES

Ball Mill Grinding William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsA Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls Material fed through the mill is crushed by impact and ground by attrition between the balls The grinding media are usually made of highchromium steelThe smaller grades are occasionally cylindrical ("pebs Cement mill WikipediaThe Handling Materials and Main Types of Ball Mill: Ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etcIndustrial Ball Grinding Mill Manufacturer, Ball Mill

Effect of grinding aids in cement grinding

Laboratory experimental work was also conducted to study the effect of various types of grinding additives on product fineness and compressability Triethanolamine (TEA), Ethylene Glycol (EG) and CEMEX (commercial grinding additives) was tested at various dosage in ball grinding mill at fixed grinding condition (ball size, speed and filling ratio)23 Grinding mill and studies A stirred ball grinding mill, manufactured by Drais werke GmbH, Germany, was employed for the grind ing tests A diagrammatic representation of the mill in continuous mode is shown in Figure 2 The grind ing was carried out in a 150mmdiameter by 420mm long stainless chamber equipped with seven 120mmDispersants in Stirred Ball Mill Grinding tIn fine grinding of cement in a ball mill, it is sometimes impractical to grind finer in a dry state Even though the chemical reactivity requires the material to be dry ground, it is sometimes necessary to use different breakage machines to obtain the product, but it is usually more expensive, requires more energy and reduces capacity The economic alternative is to use a grinding aidEffect of Grinding Aids in Cement Grinding NASA/ADS

Effect of ball and feed particle size distribution on the

6/1/2018 During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig 1A chemical reaction on the other hand can consist of say reactant ‘A’ forming intermediate product ‘B’ then proceeding to final product ‘C’ or a competing reactant ‘A’ to final product ‘D’ can also Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84TECHNICAL NOTES 8 GRINDING R P KingThe Handling Materials and Main Types of Ball Mill: Ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etcIndustrial Ball Grinding Mill Manufacturer, Ball Mill

Effect of ball and feed particle size distribution on the

6/1/2018 During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig 1A chemical reaction on the other hand can consist of say reactant ‘A’ forming intermediate product ‘B’ then proceeding to final product ‘C’ or a competing reactant ‘A’ to final product ‘D’ can also Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William BoultonThe “ballless“ has not yet been achieved because the grinding effect of the ball mill is more in line with the requirements of cement performance Thus, if the ball mill can reduce power consumption or even its power consumption than the vertical mill by some means, it can survive the cement grinding processCeramic ball change ball mill output reduction can improve

Ball Size Analysis in SAG Grinding Grinding

Also increasing the proportion of grinding media without regard to the total grinding volume available in a mill may start affecting the grinding / throughput rate You can add to the discussion the effect of ball trajectory where they should land in the charge, liner wear, lifter height ball 23 Grinding mill and studies A stirred ball grinding mill, manufactured by Drais werke GmbH, Germany, was employed for the grind ing tests A diagrammatic representation of the mill in continuous mode is shown in Figure 2 The grind ing was carried out in a 150mmdiameter by 420mm long stainless chamber equipped with seven 120mmDispersants in Stirred Ball Mill Grinding tLaboratory experimental work was also conducted to study the effect of various types of grinding additives on product fineness and compressability Triethanolamine (TEA), Ethylene Glycol (EG) and CEMEX (commercial grinding additives) was tested at various dosage in ball grinding mill at fixed grinding condition (ball size, speed and filling ratio)Effect of grinding aids in cement grinding

(PDF) Process Engineering with Planetary Ball Mills

The internal shape of planetary ball mill jars was modified to increase the efficiency of the milling process Four new jar designs are presented, where obstacles on the surface of a traditional Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84TECHNICAL NOTES 8 GRINDING R P King3HEAT TREATMENT STUDY 31 Pretest Treatment The ascast grinding balls with the diameter of 110 mm were selected randomly from the grinding balls produced by the sandcoating process in the iron mould, and 16 standard impact samples with the dimension of 55mm * l0 mm * l0 mm were cut by linear cutting machineNo shrinkage or porosity was found in the sample taken from the middle of the Effects of Heat Treatment Process on Microstructure and