عنا

مرحبا هل يمكنني مساعدتك؟

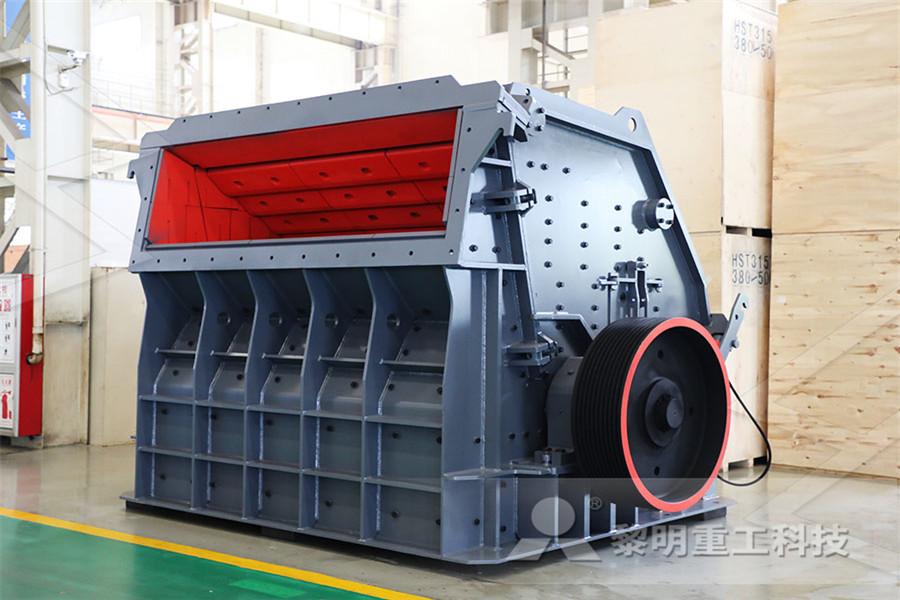

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

inch ball mill specification

2022-12-15T23:12:46+00:00

specifications of cement grinding ball

specification of cement ball grinder mill Tube ball mill or cement tube mill is designed on the basis of traditional ball mill Compared with the ball mill with same specification, cement ball mill has higher productivity and finer particle size In addition, the surface is much wider We can say that tube mill is a kind of new type grinding machine for cement production WorkingSpeTool 14411 Ball Nose Carbide End Mill Cutter Router Bits Double Flutes Spiral Milling Tool 1/4 inch Shank with 3 inch Over Length by SpeTool $1699 $ 16 99Amazon: Ball Nose End Mills: Industrial ScientificSpecification: Weight: ball mill: Customized Motor Type: AC Motor Type: Ball Mill We offer Ceramic Ball Mill for Industrial Grinding, it is used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and Ball Grinding Mill at Best Price in India

specification for steel ball for ball mill

100 1/2 inch Diameter Chrome Steel Bearing Balls G25 Ball This 1/2 inch diameter chrome steel G25 bearing balls are for use in single and double row bearings that support radial loads These bearing balls have a 1/2 inch diameter and are grade G25 for precision relative to sphericity surface integrity and size They are made of chrome steel for durability and resistance to deformity under Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mills Mine Shank Diameter Tolerances: End Mill Style: Other Specification: Niagara Cutter Tolerance: All Inch Shanks (0001 / 0005) All Metric Shank: Specification per DIN 1835 Form BNiagara Cutter

Ball Mill – Ball Mills at Best Price in India

This Ball Mill – is a very sturdy attachment and mainly used for grinding crystalline materials and for the mixing of dry materials The Ball Mill consists of the transmission drive, stand of the Ball Mill and the Ball Mill it self The jar is stainless steel and contains balls, which vary in diameter for 30 to 40 mmMetallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll Ball Mills Mineral Processing Metallurgy3 axis c7 ball screws with double multi track ball nuts 6 ground columns with linear bearings for z axis 3 axis dro with exclusive lathemill swap display 1 7/1620 drawbar swing away computer and monitor mount full cabinet enclosure casters on bench for easy moving 1 r8 drill chuck arbor telescoping tailstock fold away handles on x,y and z axesSpecifications for the Shopmaster Mill Turn shows all

Fishing Services Catalog Weatherford International

Mill 1) to grind up or pulverize; 2) a fishing tool or shoe (junk mill) with diamond or tungstencarbide cutting edges used to grind away a fish such as stuck tools or pipe in a wellShank Diameter Tolerances: End Mill Style: Other Specification: Niagara Cutter Tolerance: All Inch Shanks (0001 / 0005) All Metric Shank: Specification per DIN 1835 Form BNiagara Cutter3 axis c7 ball screws with double multi track ball nuts 6 ground columns with linear bearings for z axis 3 axis dro with exclusive lathemill swap display 1 7/1620 drawbar swing away computer and monitor mount full cabinet enclosure casters on bench for easy moving 1 r8 drill chuck arbor telescoping tailstock fold away handles on x,y and z axesSpecifications for the Shopmaster Mill Turn shows all

Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotati80010006 2Flute M2 Ball Nose End Mill Set WC HHIP 2Flute M2 Ball Nose End Mill Set Includes 1 each of sizes 1/8, 3/16, 1/4, 5/16, 3/8 1/2" Made of HighSpeed steel Center Cut, Singleend Full radius cutting edge Designed for milling radius bottom HHIP 80010006 2Flute M2 Ball Nose End Mill Set, 1/8"1/2 end mill, VF3XB shows high fracture resistance End mill Workpiece Revolution Feed rate Machining method 1,500mm/min (0038mm/t) Air blow Feed rate increased by 50% End mill Workpiece Revolution Feed rate Machining method 3,400mm/min (008mm/t) Coolant mist Feed rate increased by 60% End Mill Series MITSUBISHI MATERIALS CORPORATION

Ball End Mills MSC Industrial Supply

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting 2flute highprecision finishing carbide ball end mill for highhardness steels chipping resistance is enhanced in combination with the weaker helix angle specification List 8410 2 Flute, Inch, DUROREY Coating View Offering > View Overview > Alternate Products List 8510 2 OSG Taps End Mills Drills Indexable Composite You can easily convert inch dimension to mm by multiplying it with 254 and rounding as follow; Outside diameter above 16 inches rounded to nearest 1 mm Outside diameter 16 inches and below rounded to A Complete Guide to Pipe Sizes and Pipe Schedule – Free

Bearing Specification Guide Kosser

BALL BEARINGS44 • Conrad Deep Groove Types R Inch Series/30 Series/100 Series/200 Series/ 300 Series/400 Series/Cartridge – W Series/Wide Inner Ring (7000 Series/8000 Series/ Series/88000 Series) • Maximum Capacity Types 1200 Series/1300 Series/1400 SeriesBall valves are one of the most common valve types used in both residential plumbing and industrial processes They are typically used for basic on/off service For this reason they are referred to as shutoff valves, isolation valves, or stop valves They are operated with a simple 90 degree turn (qurterturn) of a sphere shaped obstructor or Ball Valve Selection Guide Assured AutomationBall valves are one of the most common valve types used in both residential plumbing and industrial processes They are typically used for basic on/off service For this reason they are referred to as shutoff valves, isolation valves, or stop valves They are operated with a simple 90 degree turn (qurterturn) of a sphere shaped obstructor or Ball Valve Selection Guide Assured Automation

Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotatiInch BALL ACME LEAD SCREW TECHNICAL INFORMATION MAXIMUM LENGTH (IN) ADJUSTED FOR BEARING SUPPORT “Y” DIMENSION PURPOSE This graph was designed to simplify the selection of the proper lead screw so as to avoid lengths and speeds BALL ACME LEAD SCREW TECHNICAL INFORMATION I80010006 2Flute M2 Ball Nose End Mill Set WC HHIP 2Flute M2 Ball Nose End Mill Set Includes 1 each of sizes 1/8, 3/16, 1/4, 5/16, 3/8 1/2" Made of HighSpeed steel Center Cut, Singleend Full radius cutting edge Designed for milling radius bottom HHIP 80010006 2Flute M2 Ball Nose End Mill Set, 1/8"1/2

Baltec Ball Material Selection

Ball Screws Ball screws are very similar to ball bearings in that they generally use either chrome steel or type 440C hard stainless steel A peculiarity of ball screws is that they typically have a load ball and the next ball is a 001inch undersized spacer ball, and so on(B1201) Pipe Threads General Purpose (Inch) MSS (Manufacturers Standardization Society) MSSSP6 Standard Finishes For Contact Faces Of Pipe Flanges And Connection End Flanges Of Valves And Fittings Ball Valves With Flanged Or Butt Welding Ends For General ServiceActuator Sizing, Standards and Specifications for Floating 11125 One mill hole for inspection purposes not to exceed 5/8 inch (159 mm) in diameter and 1/8 inch (32 mm) in depth 1113 Balance 11131 The following tolerances shall be permissible in the balance of a bowling ball used in sanctionedUpdate on Ball Specification Rule – BTBA

Ball End Mills MSC Industrial Supply

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting BALL MILL SPECIFICATION PDF Mine Equipments Overview on the grinding mills and their dual pinion mill drives Figure 3 The 24' x 395' ball millTable 4, 5 and 6 include the technical data for the Copper Mountain ball millsTable 4 general ball mill dataSpecification Get Priceball mill specsThis specification prescribes the minimum mandatory requirements governing the design, sizing, and selection of control valves 11 Equipment and services furnished by the Seller shall include: 111 Design, fabrication, testing and delivery of all valves, complete with actuators and accessories to meet the requirements of this specification andControl Valve Technical Specification ICEweb

HHIP 80010006 2Flute M2 Ball Nose End Mill Set, 1/8"1/2

80010006 2Flute M2 Ball Nose End Mill Set WC HHIP 2Flute M2 Ball Nose End Mill Set Includes 1 each of sizes 1/8, 3/16, 1/4, 5/16, 3/8 1/2" Made of HighSpeed steel Center Cut, Singleend Full radius cutting edge Designed for milling radius bottom Every mining operation has a unique grinding process Variable needs require versatile grinding equipment offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needsGrinding mills for mining and minerals processing Ball Mill is the key equipment for smash the materials after they are primarily crushed Ball Mill isgenerally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns Ball Milll is an efficient tool for grinding many materials into fine powderChina Gold Processing Mining Machine Grinding Ball Mill

End Mills Milling GUHRING

5MM GF300 Ball Carbide ball nose end mill nanoSi EDP/Part Number: 00: Series Number: 3359: Order Code: 5000: 8MM RF100 Diver end mill nanoSi EDP/Part Number: 00: Series Number: 6737: Order Code: 8000: 3/8" UNI PRO CARBIDE end mill Uncoated EDP/Part Number: 00: Series Number: 3168 ball mill specs Ball Mill Design And Different Specs czeueu A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, Different materials are used as media, Get Price And Support Online; design specifications of ball mill liners – Grinding Mill Ball Mill Machine Design And Specifications design specifications of ball mill liners inball mill specsPrecision instrument ball bearings (Metric series) AFBMA/ANSI Std 122Class 3P Class 5P Class 5T Class 7P Class 7T Class 9P Precision instrument ball bearings (Inch series) ISO ISO 492 Normal class Class 6X Class 6 Class 5 Class 4 Class 2 Radial bearings ISO 199 Normal class Class 6 Class 5 Class 4Thrust ball bearings ISO Ball Bearings Specifications Engineering360

Baltec Ball Material Selection

Ball Screws Ball screws are very similar to ball bearings in that they generally use either chrome steel or type 440C hard stainless steel A peculiarity of ball screws is that they typically have a load ball and the next ball is a 001inch undersized spacer ball, and so on* effective feed particle size: 20/25 mm or 08 – 1 inch * output particle size: 200 – 20 mesh * all models are supplied with electric motors * control panels are supplied optionally * dove reserves the right to modify the specification at anytime, without prior noticeBall Mills, grinders, crushers, ball mill grinding Specification: Weight: ball mill: Customized Motor Type: AC Motor Type: Ball Mill We offer Ceramic Ball Mill for Industrial Grinding, it is used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and Ceramic Ball Mill Machine at Best Price in India

Carbide End Mills Solid Carbide End Mills Regal

Regal Cutting Tools produces a complete line of carbide and solid carbide end mills manufactured from ultramicro grain carbide that improves hardness while maintaining toughness Carbide and solid carbide end mills are designed for machining operations in a variety of materials to