عنا

مرحبا هل يمكنني مساعدتك؟

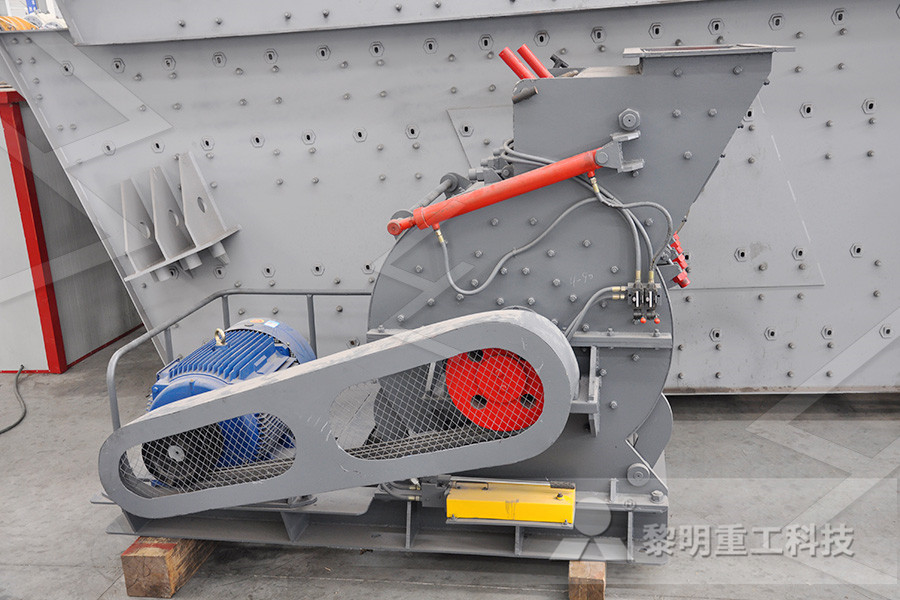

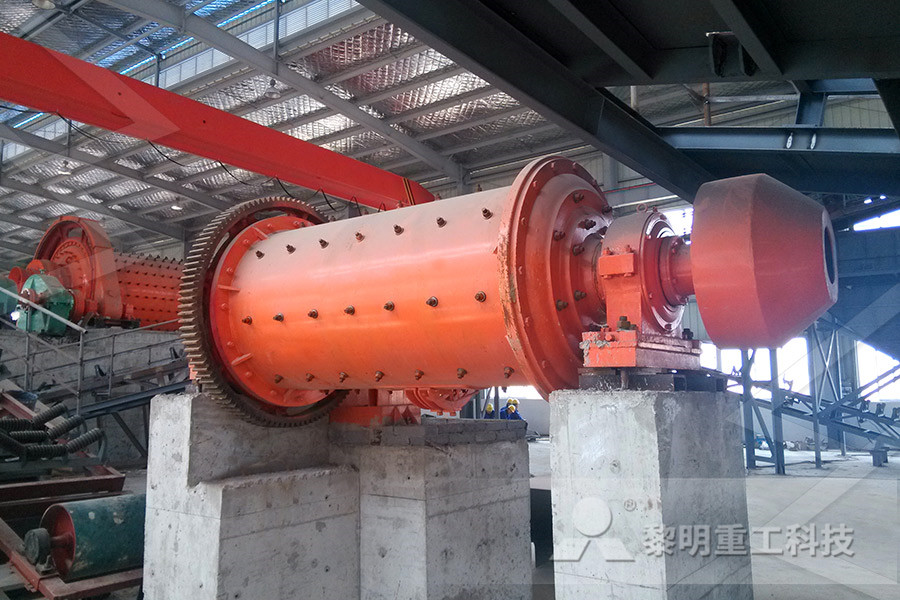

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

type of crusher jaw crusher

2020-02-13T10:02:56+00:00

Crushers an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactA jaw crusher is a compression type of crusher feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel with the discharge size controlled by the gap setting ie the space between those two pieces of steel the tighter the setting the smaller the output size and the lower the throughput capacity Jaw CrusherType Of Material CrusherThe gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect Topics

What is a Jaw Crusher? Telsmith

A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher otherwise, known as Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage Types of CrushersJaw crusher type 1 JC series jaw crusher Optimized motion parameters, wedge block discharge opening adjustment, steel plate toggle plate, oversize bearing design, integral steel frame baseIntroduction of Jaw Crusher Type and Jaw Crusher Technical

Different Types of Rock Crushers – Crusher Rental Sales

The jaw crusher is usually made of cast steel because it is such a heavy duty machine There are three types of jaw crushers: Blake crusher, Dodge crusher, and the Universal crusher The type of jaw varies, which makes the different jaw crushers preferred for certain projects For example, the Dodge crusher is used for laboratory purposes and 7/28/2020 Jaw crusher working principles When movable jaw moves down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw moves away from the fixed jaw under the action of the pull rod and spring so that the materials which have been crushed are discharged from the outlet of crushing chamber4 Types of Stone Crushers' Maintenace and Efficient 4/3/2015 Jaw crusher Jaw crusher is used as primary crusher It uses compressive force for breaking the material This mechanical pressure is achieved by the two jaws of the crusher Reduction ratio is usually 6:1 The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other than Crushers and Their Types – IspatGuru

What is a Jaw Crusher? Telsmith

A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher otherwise, known as Jaw crusher type 1 JC series jaw crusher Optimized motion parameters, wedge block discharge opening adjustment, steel plate toggle plate, oversize bearing design, integral steel frame baseIntroduction of Jaw Crusher Type and Jaw Crusher Technical Jaw Crusher Laboratory Type We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel Jaw Crusher Laboratory Type entdeckcostaricade

Jaw Crusher for Sale in Philippines Click for Price List

Small type Jaw Crusher for Sale – PE150*250 ~ PE500*750 The output of this small jaw crusher: 40110t/h, the maximum feed size: 425mm, and the Discharging granularity: 50100mm It is suitable for primary and secondary crushing of all kinds of minerals and Metallurgical ContentJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw Jaw Crusher Working Principle8/14/2019 The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineAnalyzing the operation and design of a Jaw Crusher using

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPHEuropean Type Jaw Crusher Crusher European Type Jaw Crusher adopts good technology and highend raw materials, which can crush hard stones or ores Based on advantages of excellent quality, large output and long service life, this machine can be widely used in JoyalEuropean Type Jaw Crusher,European Type Jaw Crusher Working Principle of Jaw Crusher: You might ask that how a jaw type crusher works Here, I will introduce its working principle: When the rock crushing machine works, motor drives belt and pulley, and the eccentric shaft drives the mobile jaw plate When the mobile jaw plate rises, the angle between elbow plate and mobile jaw plate becomes largerJaw Crusher Turn Waste Concrete into Sand

Types of Crushers

Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently For 45 years, C Series jaw crushers have proven their reliability in different primary crushing operations in aggregates, mining and recycling applications, with up to 11,000 jaw crusher installationsJaw crushers Jaw crusher is a type of rock crusher It can be divided into two major types according to its different working principle, Doubletoggle jaw crusher and overhead eccentric jaw crusher Of course, both of the two types of jaw crushers can be used to crush stones You need to choose the right type when you need to use a jaw crusherDifferent Types of Jaw Crusher sanmechina

Jaw Crusher Turn Waste Concrete into Sand

Working Principle of Jaw Crusher: You might ask that how a jaw type crusher works Here, I will introduce its working principle: When the rock crushing machine works, motor drives belt and pulley, and the eccentric shaft drives the mobile jaw plate When the mobile jaw plate rises, the angle between elbow plate and mobile jaw plate becomes larger8/16/2020 A jaw crusher refers to a type of crusher A crusher is a machine that breaks material, usually rocks, into smaller pieces Jaw crushers are most often seen in mining or disposal, where they are used to break objects into smaller pieces Used in processing facilities and on construction sites, jaw What is a Jaw Crusher? (with pictures)ASD Series Jaw Crusher is the new generation of jaw crusher with optimized and developed design, which is based on absorbing the international advanced technology Compared with the equivalentsize crusher, ASD jaw crusher exceeds with better capacity, bigger crushing ratio, lower running cost, as well as the friendly, stable and reliable operationASD Series Jaw Crusher Luoyang Dahua

Types Of Stone Crushers Crusher Mills, Cone Crusher, Jaw

Jaw Crusher, Double Toggle Oil Type Stone Crusher Our clients can avail from us, an array of Secondary Jaw Crushers that is designed inaccordance with international quality standards These are widely used for Small type Jaw Crusher for Sale – PE150*250 ~ PE500*750 The output of this small jaw crusher: 40110t/h, the maximum feed size: 425mm, and the Discharging granularity: 50100mm It is suitable for primary and secondary crushing of all kinds of minerals and Jaw Crusher for Sale in Philippines Click for Price List 8/14/2019 The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineAnalyzing the operation and design of a Jaw Crusher using

Jaw Crusher Working Principle

Metallurgical ContentJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw FL 42 Role of flywheel in a jaw crusher 32 12 Double toggle blake type jaw Function Of Jaw Crusher Jaw crusher functions and parts shown in figure 1 [5] II Read more function of toggle joint in jaw crusher function of toggle joint in jaw crusher As a leading global manufacturer of crushing and milling equipment, we offer advanced Function Of Toggle Plate In Jaw CrusherA fixed jaw crusher commonly consists of three main parts, frame, jaw plate and side guard plate, and plays a crucial role in stone crushing plant and sand production line Impact Rock Crusher Impact Rock Crusher is a type of crushing machine applied to metallurgy, gold mine, chemistry, building material and hydro project industryFixed Crusher is a stone crusher equipment

PEW European Type Jaw Crusher greatwallcrusher

PEW European jaw crusher is a new type of jaw crusher designed and produced by our company on the basis of absorbing advanced jaw crusher technology from Europe and America It is used for coarse crushing, medium crushing of all kinds of ores and rocks, much more advantageous when crushing hard material Widely used in mines, building materials 8/16/2020 A jaw crusher refers to a type of crusher A crusher is a machine that breaks material, usually rocks, into smaller pieces Jaw crushers are most often seen in mining or disposal, where they are used to break objects into smaller pieces Used in processing facilities and on construction sites, jaw What is a Jaw Crusher? (with pictures)Crusher Versus Jaw Crusher Advantage of jaw crusher versus impact crusherWe are a professional mining machinery manufacturer, the main equipment including jaw crusher, cone crusher and other sandstone equipmentball mill, flotation machine, concentrator and other beneficiation equipment powder grinding plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentCrusher Versus Jaw Crusher

Types Of Stone Crushers Crusher Mills, Cone Crusher, Jaw

Jaw Crusher, Double Toggle Oil Type Stone Crusher Our clients can avail from us, an array of Secondary Jaw Crushers that is designed inaccordance with international quality standards These are widely used for Material type: pebble, bluestone, granite, river pebble, etc Equipment configuration: jaw crusher (coarse crusher), impact crusher (fine crusher), vibrating screen, belt conveyor, etc Finished product specification: 05mm, 510mm, 1020mmjaw crusher machine capacity of tons in south africaIn doubletoggle jaw crushers, the pitman is mounted on fixed noneccentric shaft that situated at the top of the crusher There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven camshaftWhat is a Jaw Crusher? – MEKA Crushing Equipment

pe jaw crusher, jaw crusher price, jaw crusher for sale

PE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields 0086371Also is the most mainstream crusher type Jaw crusher is usually used as a primary crusher and secondclass crusher Cone crusher is usually used as secondary crusher or threestage crusher machine Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages Jaw crusher breaks the rock to 10 ~ 30 cm sizeJaw Crusher VS Cone Crusher Advantages and DisadvantagesBasing on the actual industrial and mineral situation of gravel industry, Fote produces the new type jaw crusher machine Since the stone jaw crusher machine enjoys the features of advanced technical process and unique structural design, the finished products can be in PE Jaw Crusher Machine, Small Jaw Crusher Price, Stone