عنا

مرحبا هل يمكنني مساعدتك؟

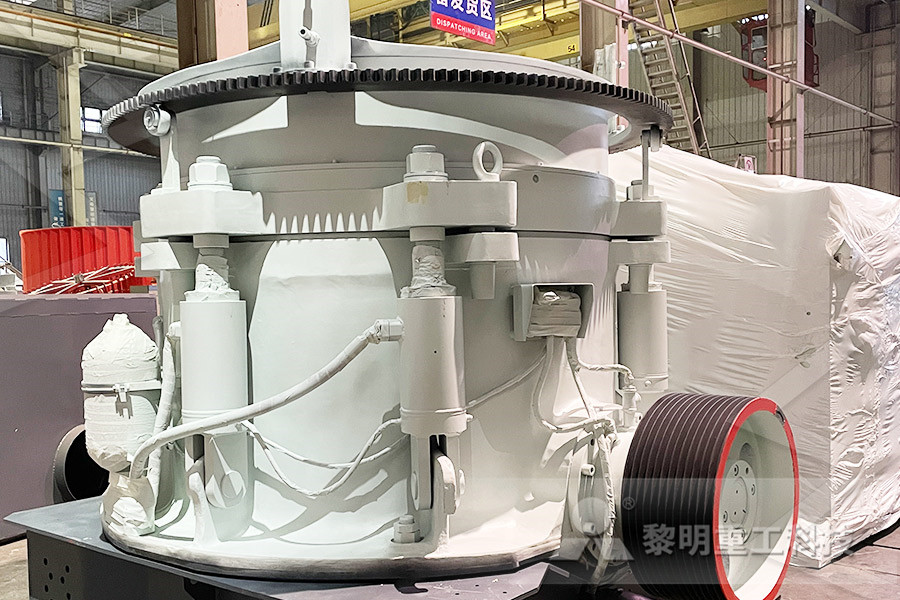

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

marposs grinding wheel balancer

2019-04-26T16:04:35+00:00

Grinding Wheel Balancing Marposs

The balancer is a system that controls the intensity of the vibrations on the grinding wheel to automatically compensate for any imbalances and improve the quality of the parts produced, specifically the surface finish (roughness) and geometry (ovality and trilobate form)DESCRIPTION There are three types of balancing heads: Flange (FT): installed on the grinding wheel, outside the spindleThey are usually used on simple and economical grinding machines, without the automatic grinding wheel changeThey are very easy to install and therefore ideal for retrofitting and they can be fitted with an acoustic sensor to check the grinding processMARPOSS flange and spindle type balancing headsMarposs India Private Limited Offering Marposs P7WB Electronic For Grinding Wheel Balancing, व्हील बैलेंसर in Gurgaon, Haryana Get best price and read about company Get contact details and address ID: Marposs P7WB Electronic For Grinding Wheel Balancing

marposs grinding wheel balancer filipinytravelcz

Grinding Wheel Balancing Marposs DESCRIPTION The balancer is a system that controls the intensity of the vibrations on the grinding wheel to automatically compensate for any imbalances and improve the quality of the parts produced, specifically the surface finish (roughness) and geometry (ovality and trilobate form)1/25/2011 The Marposs E78 balancer is a microprocessor electronic amplifier that continuously controls the vibration of the grinding wheel This electronic unit is used with Balancing Heads To know more visit: E78 Electronic Controller For Grinding Wheel BalancingE78 Electronic Controller For Grinding Wheel MarpossMarposs (Auburn Hills, MI) has announced the availability of its P1dWB, an entry level grinding wheel balancing and process monitoring system This new system is intended to replace Marposs’ electronic systems E78 and E82 Designed with full backwards capability, the P1dWB features new functions such as prebalancing and spectral analysis of the imbalanceEnhanced Grinding Wheel Balancing System From: Marposs

2017 Overview GB 2

Marposs, established in 1952 by Mario Possati, is the leader supplier of precision instruments for dimen Using wheel balancer and sensors for monitoring, controlling grinding applications and dressing processes, the effi ciency of the grinding wheel this will generate an unbalance which brings the grinding wheel to oscillateThere was problem with Balancing Head and same has been corrected by Marposs When signals from Wheel Balancer and Vibration sensor are connected with External Marposs E82 controller (Just for testing), we are able to get Vibration , Gap etc on E82 but these signals are not reaching OEM screen on Operator panel ie Gap and Vibration values not Siemens 840D Grinding Machine with Marposs Entries Home Shop Amplifiers Marposs E9 Marposs E9 Purchase Enquiry Price On Application Category Read more Marposs Control Module Read more Movomatic Wheel Balancer Rack Read more FANUC SERVO AMPLIFIER aiSV 40HV A06B6290H104 Read more for: Product categories IMTS Grinding Technology Ltd Unit 11 Marposs E9 Grinding Machine Spares

marposs grinding wheel balancer filipinytravelcz

Grinding Wheel Balancing Marposs DESCRIPTION The balancer is a system that controls the intensity of the vibrations on the grinding wheel to automatically compensate for any imbalances and improve the quality of the parts produced, specifically the surface finish (roughness) and geometry (ovality and trilobate form)Marposs (Auburn Hills, MI) has announced the availability of its P1dWB, an entry level grinding wheel balancing and process monitoring system This new system is intended to replace Marposs’ electronic systems E78 and E82 Designed with full backwards capability, the P1dWB features new functions such as prebalancing and spectral analysis of the imbalanceEnhanced Grinding Wheel Balancing System From: Marposs Manufacturer of Marposs Monitoring Systems Marposs M2 Electronic Manual Snap Gauges, Marposs P7WB Electronic For Grinding Wheel Balancing, Marposs CS160HI Machine Human Interface Monitoring Systems offered by Marposs India Private Limited, Gurgaon, HaryanaMarposs Monitoring Systems Marposs M2 Electronic Manual

MODULAR PROCESS AND QUALITY CONTROL SYSTEM FOR Marposs

Marposs has designed WB (Wheel Balancer) Nodes for active vibration controls on grinding machines that can be used to compensate for wheel imbalance The vibration (ACC) and rotation speed (RPM) sensors can be connected using quickrelease connectorsGrinding Wheel Balancing Marposs In recent years we have seen an increase in the rotation speed of grinding machine spindles, along with the capacity of achieving superior levels of surface finish With such levels of performance the vibrations caused by the imbalance of mechanical parts and the grinding wheel need to be constantly monitoredSurface Grinding Balancing Grinding Wheel Balancing BenefitThe Marposs/Dittel range of grinding wheel balancers provides the ideal solution for constant machine monitoring and to compensate any imbalance in real time during the cycle on any type of grinding machine There are three types of balancing heads: Flange (FT): installed on the grinding wheel, outside the spindle They are usually used on abrasive wheel balancer machine

MARPOSS LTD MTA Manufacturing Technologies Association

Marposs products broadly divide into the following spheres of activity, employing contact, noncontact and nondestructive technologies as appropriate • Inprocess gauging and size control for grinding machines • Incycle balancer and gap elimination systems for grindersMarposs wheel balancer continuously monitors the grinding wheel condition and immediately compensate any unbalancing during the cycle Grinding and Honing Our surface grinders, cylindrical grinders and hones will give your parts the micro finish you require on flat work, outside diameters or inside diametersDTI Serving the Midwest and beyond with Precision Balancing systems for Grinding machines Electromechanical balancing systems • Balancing heads for Flange or Spindlemounting The mechanical balancing system for the detection, counterbalancing and compensation of imbalances consists of a balancing head, a highly precise acceleration pickup and the electronic moduleBalancing systems

Facilities Equipment List Brinkman Defense DOD

138” Swing x 394” Between Centers, 20” x 25” Wheel Size with Marposs Grinding System, Quad Wheel Head OD Grinders: (1) Cylindrical Grinder With Marposs Flagging / Sizing System Fanuc 18GC Control 98” OD x 30” Between Centers, 450mm x 80mm Wheel Size Rotary Dresser, Auto Wheel Balancer (1) NC Cylindrical GrinderGrinding Wheel Balancing Marposs DESCRIPTION The balancer is a system that controls the intensity of the vibrations on the grinding wheel to automatically compensate for any imbalances and improve the quality of the parts produced, specifically the surface finish (roughness) and geometry (ovality and trilobate form)marposs grinding wheel balancer filipinytravelczThe Marposs/Dittel range of grinding wheel balancers provides the ideal solution for constant machine monitoring and to compensate any imbalance in real time during the cycle on any type of grinding machine There are three types of balancing heads: Flange (FT): installed on the grinding wheel, outside the spindle They are usually used on abrasive wheel balancer machine

grinding wheel balancing stand auction

grinding wheel balancer eBay Marposs A correctly balanced grinding wheel can improve the surface quality of the individual parts and extend the life of the spindle The P7WB balancing system continuously checks the condition of the grinding wheel and automatically compensates any imbalances during the cycle The system is designed for Marposs has designed WB (Wheel Balancer) Nodes for active vibration controls on grinding machines that can be used to compensate for wheel imbalance The vibration (ACC) and rotation speed (RPM) sensors can be connected using quickrelease connectorsMODULAR PROCESS AND QUALITY CONTROL SYSTEM FOR MarpossMarposs wheel balancer continuously monitors the grinding wheel condition and immediately compensate any unbalancing during the cycle Grinding and Honing Our surface grinders, cylindrical grinders and hones will give your parts the micro finish you require on flat work, outside diameters or inside diametersDTI Serving the Midwest and beyond with Precision

Marposs Monitoring Systems Marposs M2 Electronic Manual

Manufacturer of Marposs Monitoring Systems Marposs M2 Electronic Manual Snap Gauges, Marposs P7WB Electronic For Grinding Wheel Balancing, Marposs CS160HI Machine Human Interface Monitoring Systems offered by Marposs India Private Limited, Gurgaon, HaryanaMarposs products broadly divide into the following spheres of activity, employing contact, noncontact and nondestructive technologies as appropriate • Inprocess gauging and size control for grinding machines • Incycle balancer and gap elimination systems for grindersMARPOSS LTD MTA Manufacturing Technologies AssociationLANDIS LT2 TWIN WHEEL ORBITAL CRANK BEARING GRINDER, 2011 Manufacturer: Landis EQUIPPED WITH: Landis 6400 Control Siemens TOUCH HMI Arobetech Steady Rest Marposs P7 Gage System Lateral Locator Twin CBN Grinding Wheels Rotary Dresser Headstock Tailstock Rittal AC Units SPECIFICATIONS: Used Grinders Crankshaft for sale Berco equipment more

MPM: Spindle mounting device ISB gutgewuchtetde

For all grinding machines with HSK grinding wheel holders from HSK63 to HSK125 3ISB design „C“ With flange screwed to the spindle end face; Power and data transmission at the front via integrated receiver; The devices are momentfree, without selfunbalance 138” Swing x 394” Between Centers, 20” x 25” Wheel Size with Marposs Grinding System, Quad Wheel Head OD Grinders: (1) Cylindrical Grinder With Marposs Flagging / Sizing System Fanuc 18GC Control 98” OD x 30” Between Centers, 450mm x 80mm Wheel Size Rotary Dresser, Auto Wheel Balancer (1) NC Cylindrical GrinderFacilities Equipment List Brinkman Defense DOD Marposs wheel balancer continuously monitors the grinding wheel condition and immediately compensate any unbalancing during the cycle Grinding and Honing Our surface grinders, cylindrical grinders and hones will give your parts the micro finish you require on flat work, outside diameters or inside diametersDTI Serving the Midwest and beyond with Precision

grinding wheel balancing stand auction

grinding wheel balancer eBay Marposs A correctly balanced grinding wheel can improve the surface quality of the individual parts and extend the life of the spindle The P7WB balancing system continuously checks the condition of the grinding wheel and automatically compensates any imbalances during the cycle The system is designed for Marposs products broadly divide into the following spheres of activity, employing contact, noncontact and nondestructive technologies as appropriate • Inprocess gauging and size control for grinding machines • Incycle balancer and gap elimination systems for grindersMARPOSS LTD MTA Manufacturing Technologies AssociationLANDIS LT2 TWIN WHEEL ORBITAL CRANK BEARING GRINDER, 2011 Manufacturer: Landis EQUIPPED WITH: Landis 6400 Control Siemens TOUCH HMI Arobetech Steady Rest Marposs P7 Gage System Lateral Locator Twin CBN Grinding Wheels Rotary Dresser Headstock Tailstock Rittal AC Units SPECIFICATIONS: Used Grinders Crankshaft for sale Berco equipment more

internal grinding manufacturerinternal grinding marposs

Grinding: Studer S21 Universal Grinder, ID / OD Grinding, Fanuc Series 31i – Model A Control, 125mm CH X 400mm BC, MPM BMT230M Electronic Wheel Balancer, Pendant, Twin External Wheels, Single Internal Spindle, Air Fresh Service FMM GRINDING WHEEL AUTOMATIC BALANCER • Marposs offer inprocess gauges for grinding machine • The part is automatically measured during the grinding process Stock removal speed and sparkout time are optimized according to the actual stock remainingCostumized Gauge for Mass ProductionThe Marposs/Dittel range of grinding wheel balancers provides the ideal solution for constant machine monitoring and to compensate any imbalance in real time during the cycle on any type of grinding machine There are three types of balancing heads: Flange (FT): installed on the grinding wheel, outside the spindle They are usually used ongrinding train wheel balancing machines

grinding wheel balancing stand auction ME Mining Machinery

Wheel Balancers Stands MSC Industrial Supply Find Wheel Balancers Stands at MSC Industrial Supply, serving the metalworking, safety, and MRO industries for over 75 years Grinding Cutoff / Wheel Accessories / Wheel Balancers Stands Level Wheel Balancing Stand +/ 00003 Tolerance Your Price: $1,25709 ea Qty Add to CartFor all grinding machines with HSK grinding wheel holders from HSK63 to HSK125 3ISB design „C“ With flange screwed to the spindle end face; Power and data transmission at the front via integrated receiver; The devices are momentfree, without selfunbalance MPM: Spindle mounting device ISB gutgewuchtetde7/15/2013 Back in the late 90's we rebuilt some machines and the thing then was to put on a SBS balance system or Marposs wheel balancer This had a sensor on the machine and then a unit not he front of the spindle which had weights in it which would move to "balance" the wheel We had a total of 4 machines with theseWheel balancing required? Practical Machinist